Heritage Collection

Hewn’s Heritage Collection is designed to replicate the look and texture of traditional American barnwood, featuring colors and finishes that are appropriate for both rustic and modern applications. All of our Heritage offerings feature raised wood grain, highlighting the natural uniqueness of the sustainably-sourced material that we utilize in our products.

Ohana Collection

The Ohana Collection is inspired by the sights and color palettes of Hawaii. These colors are designed to be complementary to each other, and are ideal for use as an accent element, or as your primary color choice. All of these colors feature raised wood grain, adding depth and texture that cannot be created with a standard paint application.

Shou Sugi Ban Collection

Shou Sugi Ban is a traditional Japanese technique of charring wood, usually cedar, to increase its durability and resistance to fire, insects, and rot. The process involves carefully burning the surface of the wood to create a unique blackened appearance that is both aesthetically striking and functional.

Trusted for Centuries

Cedar has a long history of being used as a building material for houses, ships, religious structures, and objects of importance, spanning from ancient times to the modern day. The Western Red Cedar that Hewn exclusively uses is sourced from regions in and around the Pacific Northwest, where cedar has long been trusted for its stability against the elements, and its protection against mold and mildew.

This proven track-record, combined with Hewn’s unique and proprietary finishes, results in a product that is unmatched and highly sought-after in the industry.

Specifications

Material

Western Red Cedar

Grade

STK (Select Tight Knot) Inland Red Cedar, Rustic appearance with sound tight knots

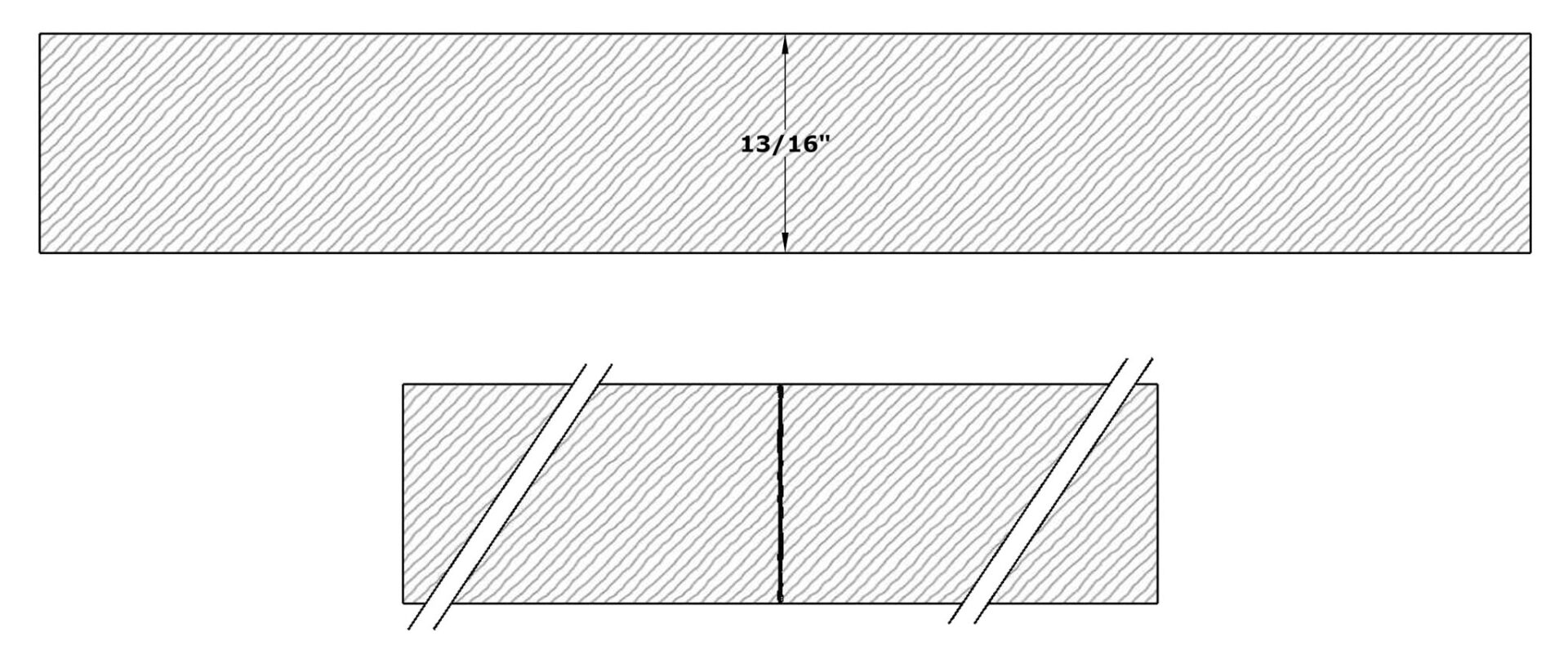

Thickness

13/16″

Lengths

6′ to 16′

(Odds and evens)

Standard Widths

1×4 (3 1⁄2” face)

1×6 (5 1⁄2” face)

1×8 (7 1⁄4” face)

1×10 (9 1⁄4” face)

1×12 (11 1⁄4” face)

Milling

Board to Board

Tongue & Groove

Shiplap

Custom

Colors

Available in Pre-Formulated and Custom Colors

Textures

Standard

Distressed

Custom

Custom Options

Hewn’s Exterior Cedar Siding can be customized to fit the individual needs and specifications of your particular project. Our finely skilled craftsmen can modify nearly any part of our in-house process to create a material designed according to your specifications, and our color technicians can match any shade or tone provided to us as part of our custom sampling process.

The Cedar Advantage

When properly maintained and cared for, Hewn’s Exterior Cedar Siding is designed to last long into the future. As with all solid-wood siding, a minor amount of regular maintenance can greatly extend the lifetime of the product, and proper industry-standard procedure at the time of install can prevent many avoidable issues.

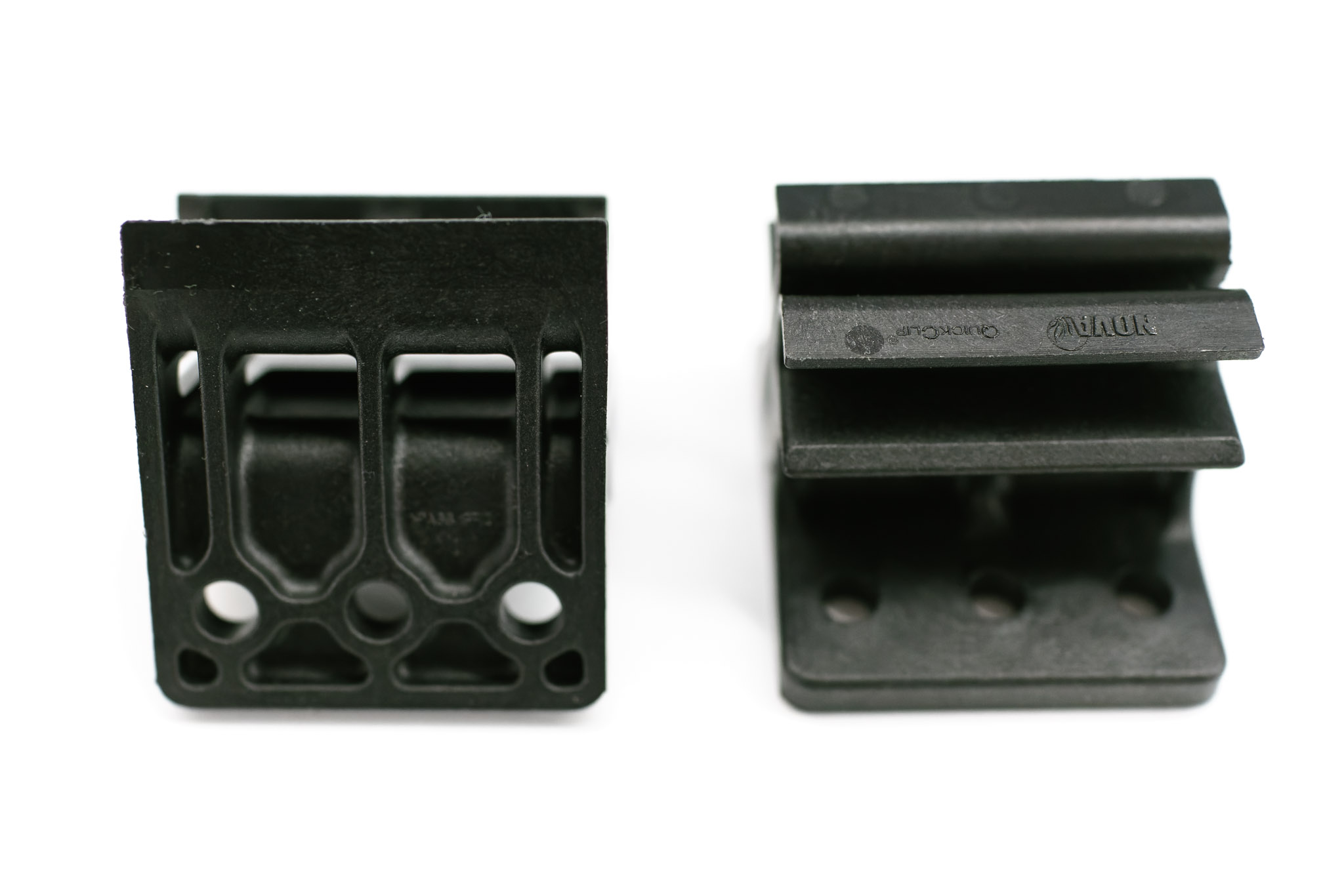

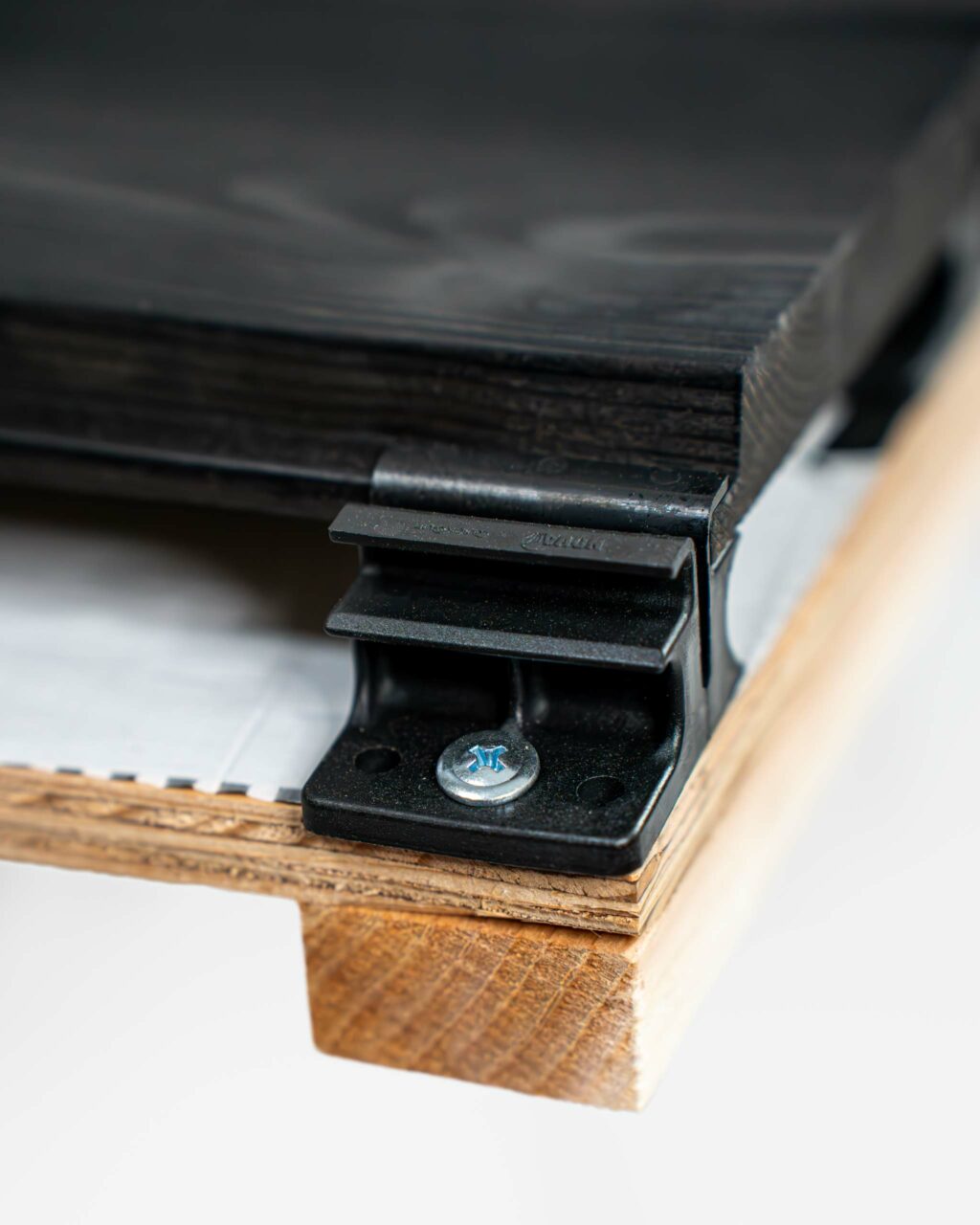

Hewn has partnered with Nova USA Wood to pair their industry-leading Rainscreen Siding ecosystem with our Hewn product offerings. Nova’s QuickClip Rainscreen Siding System is engineered by nature to withstand the test of time and the elements. Professional builders favor their products for their high quality, high performance and consistency.

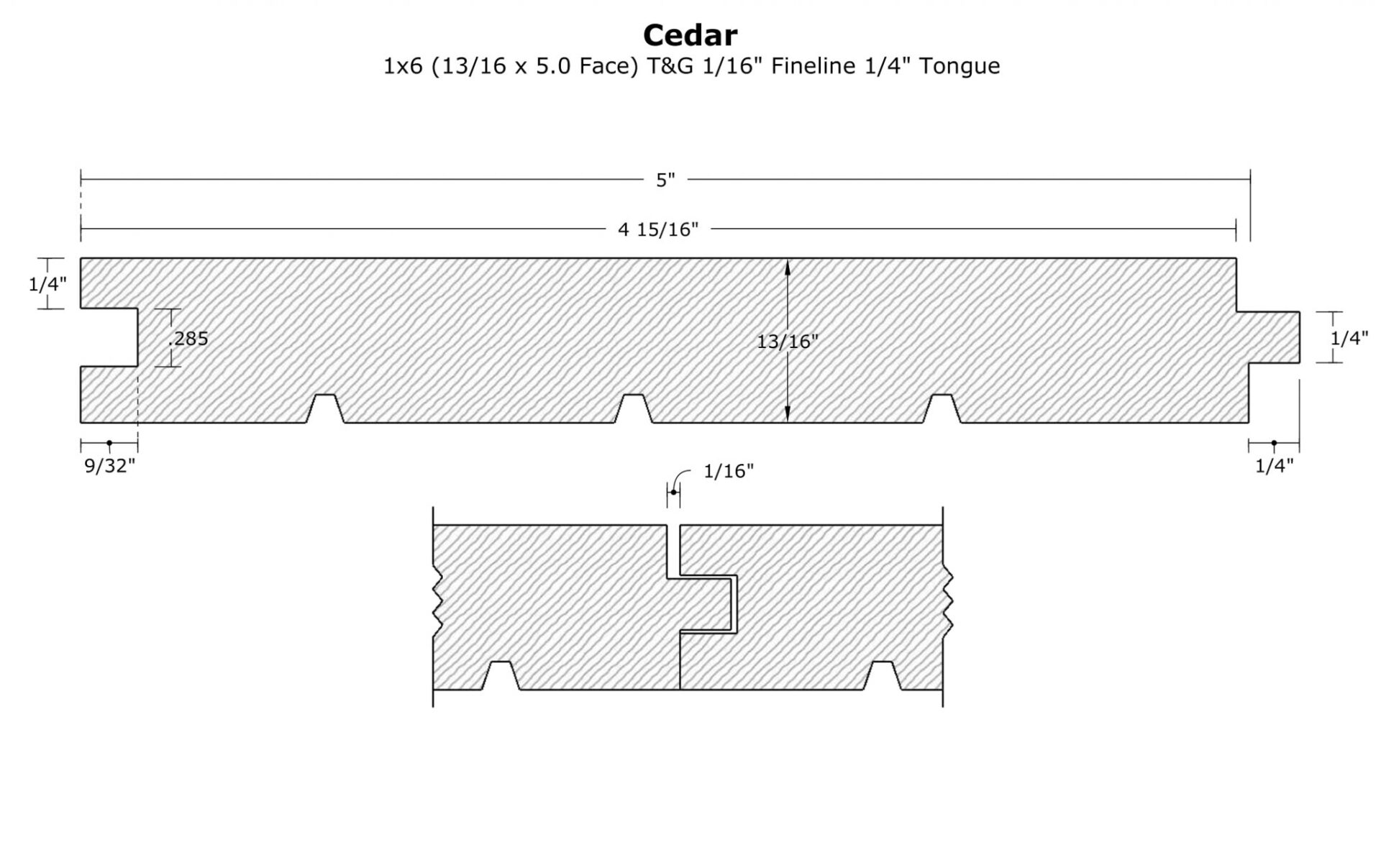

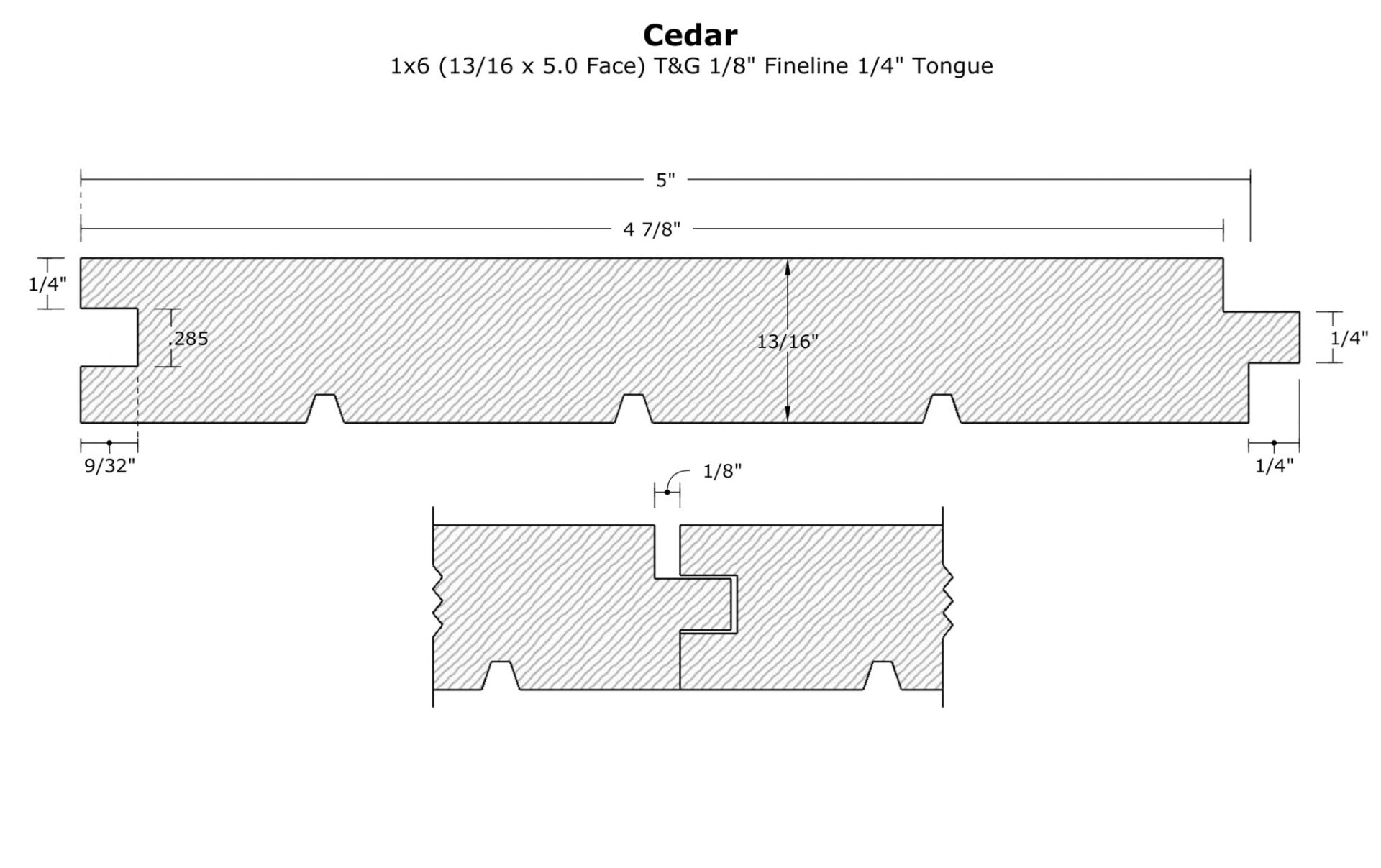

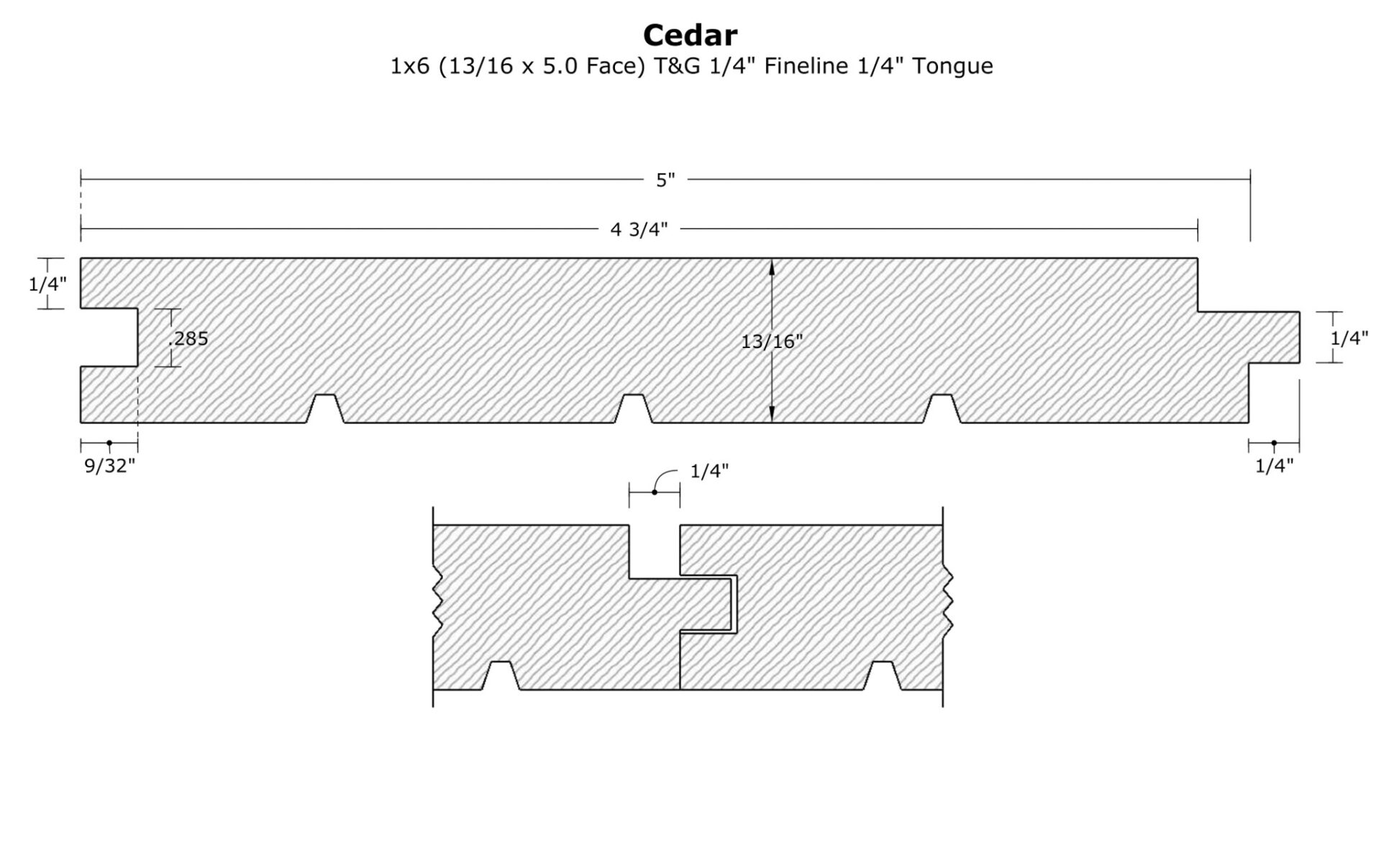

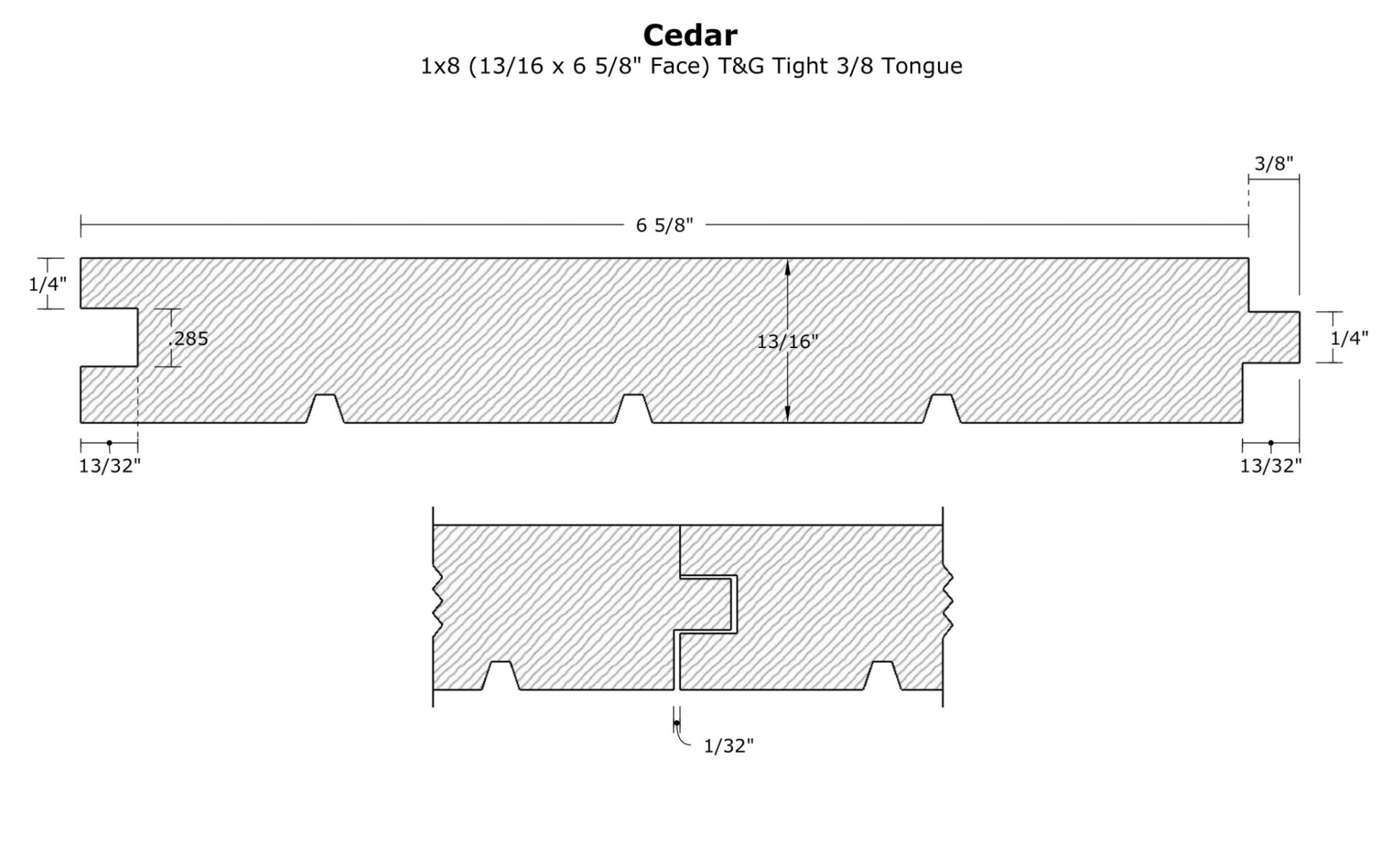

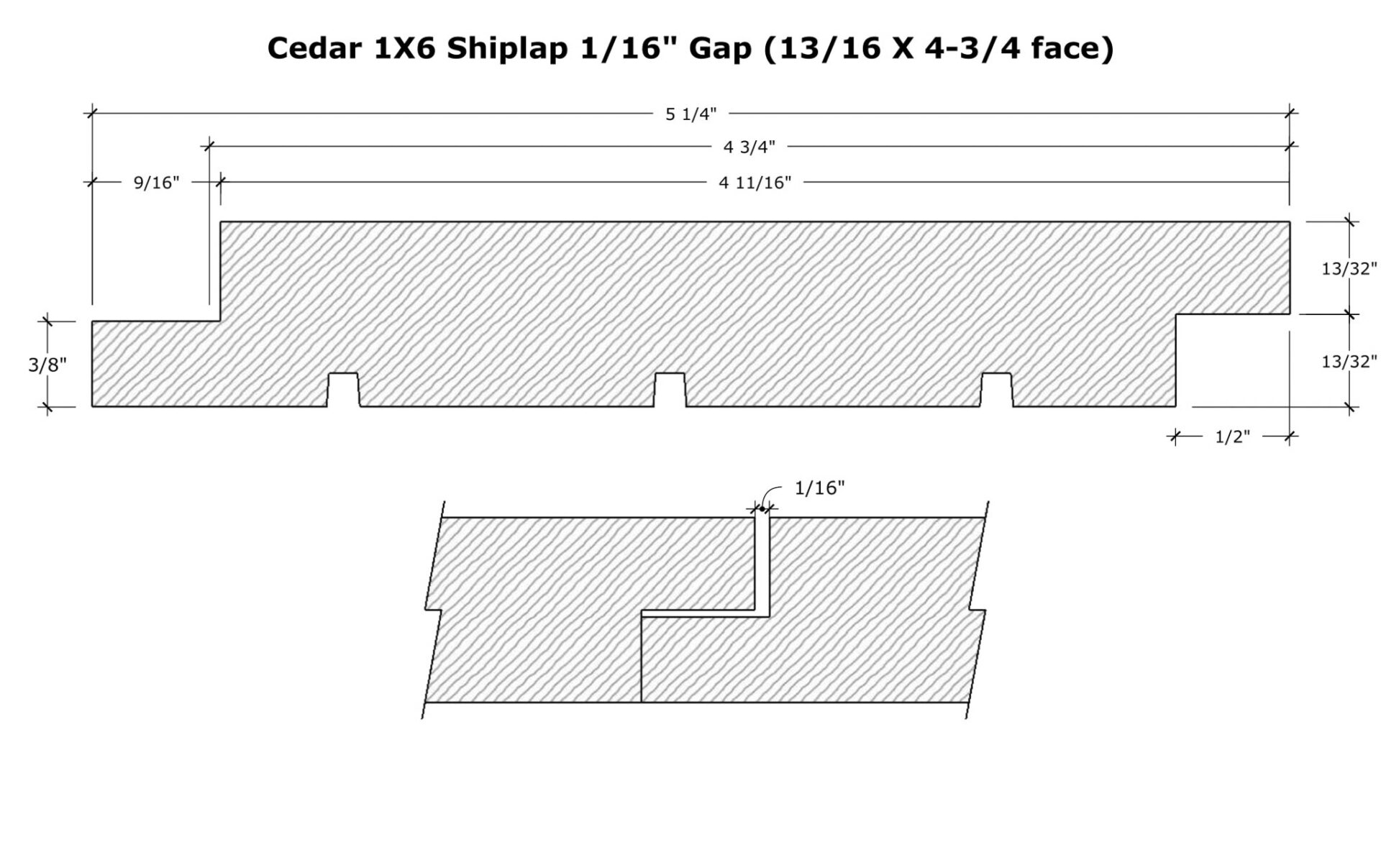

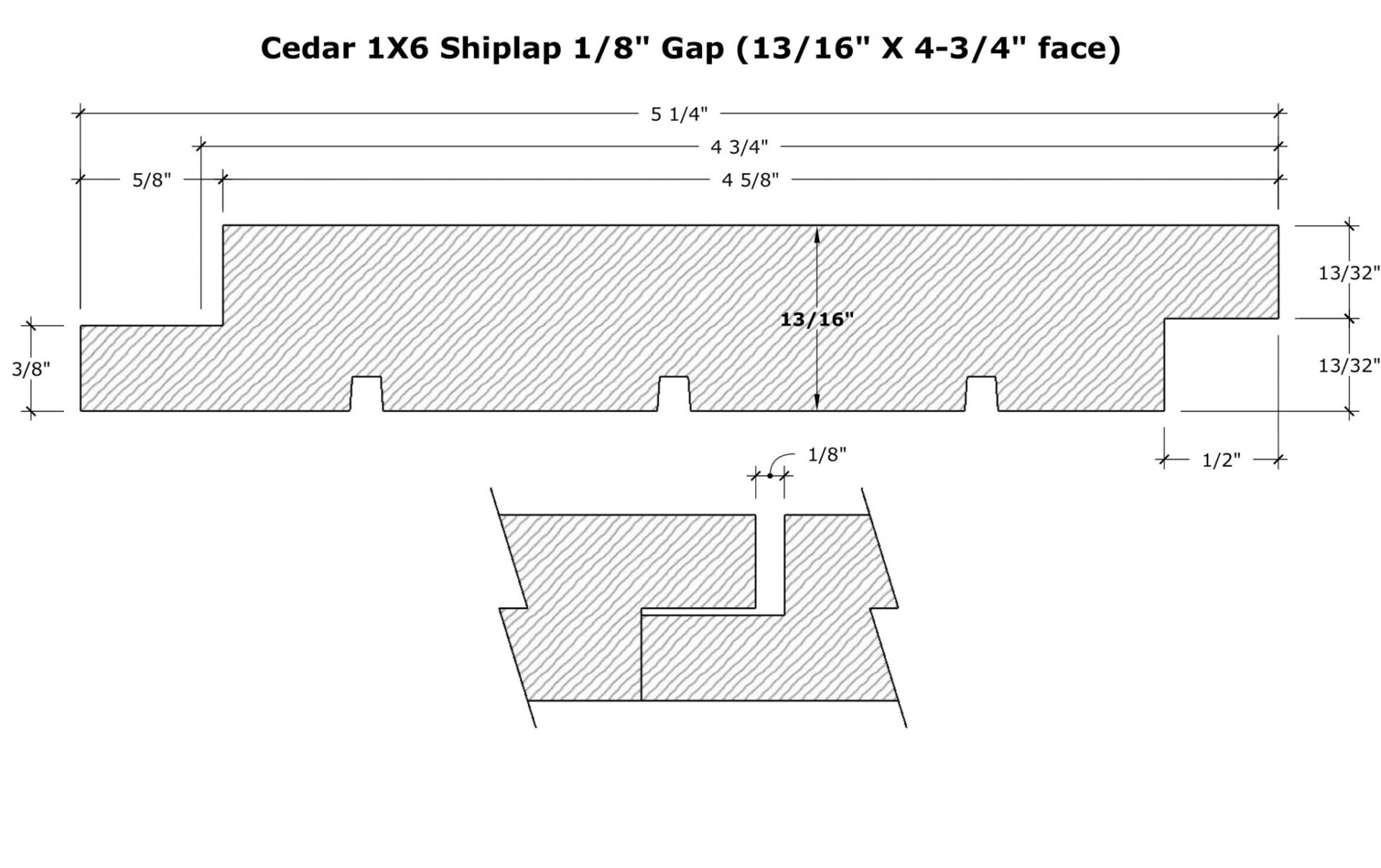

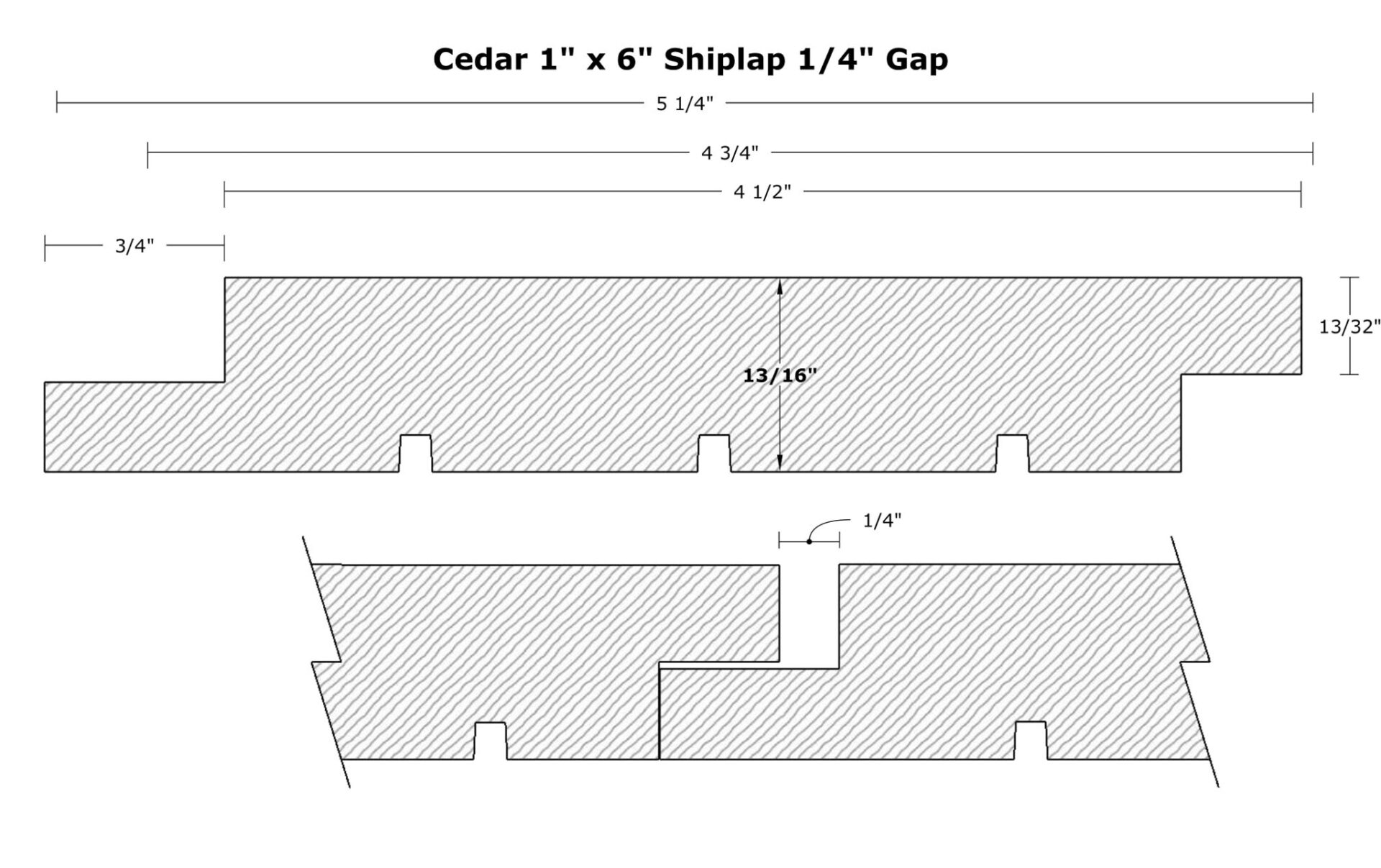

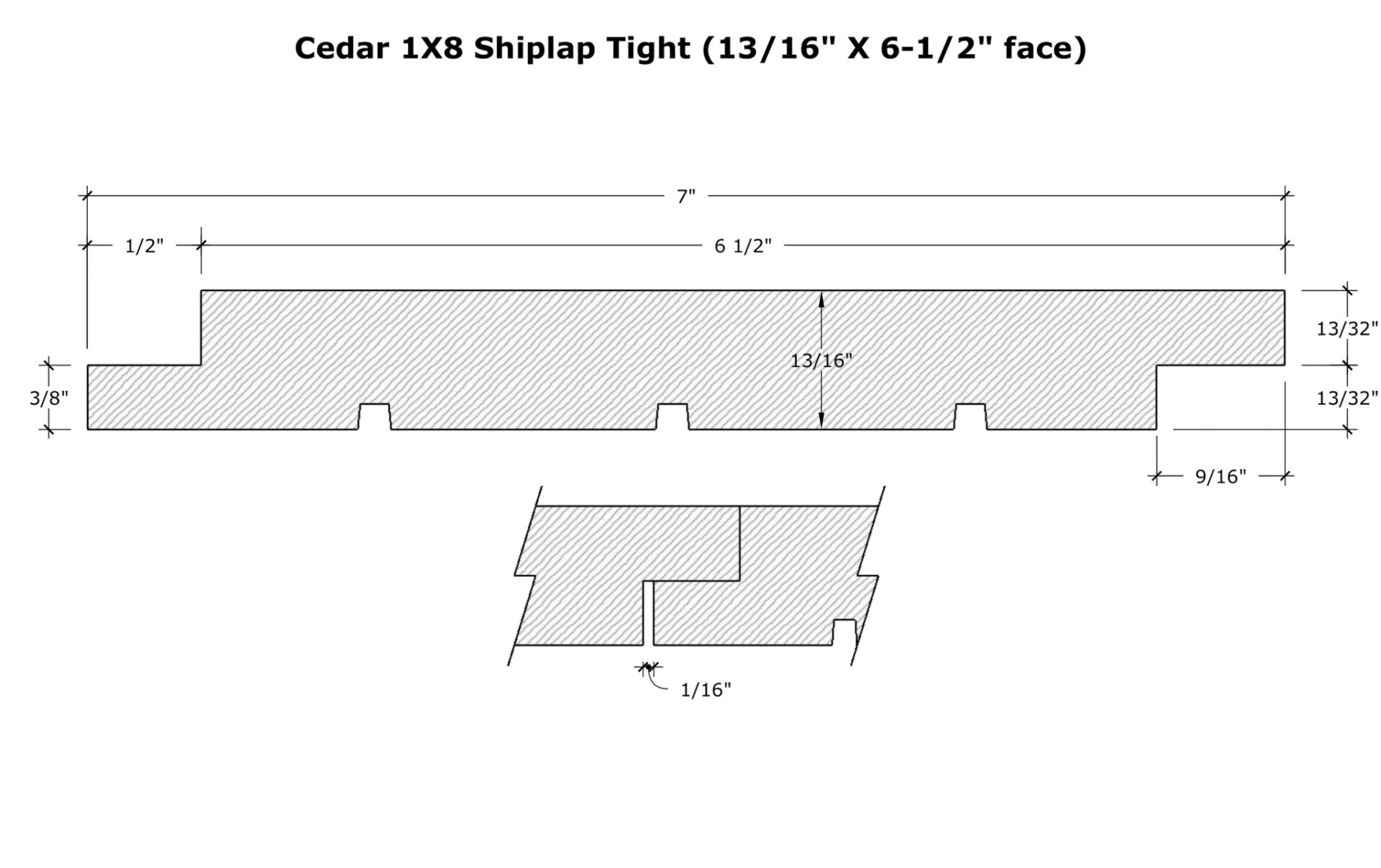

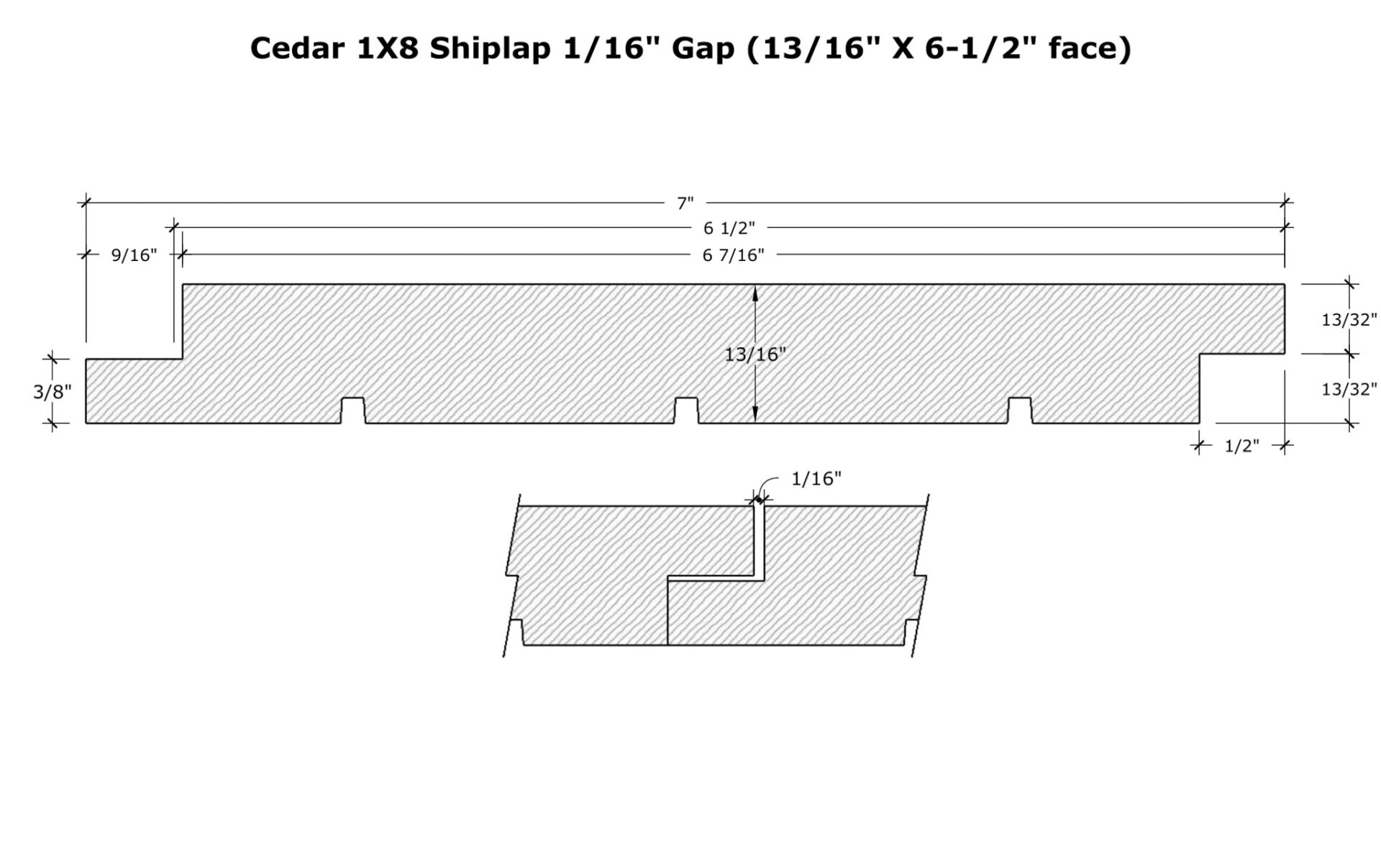

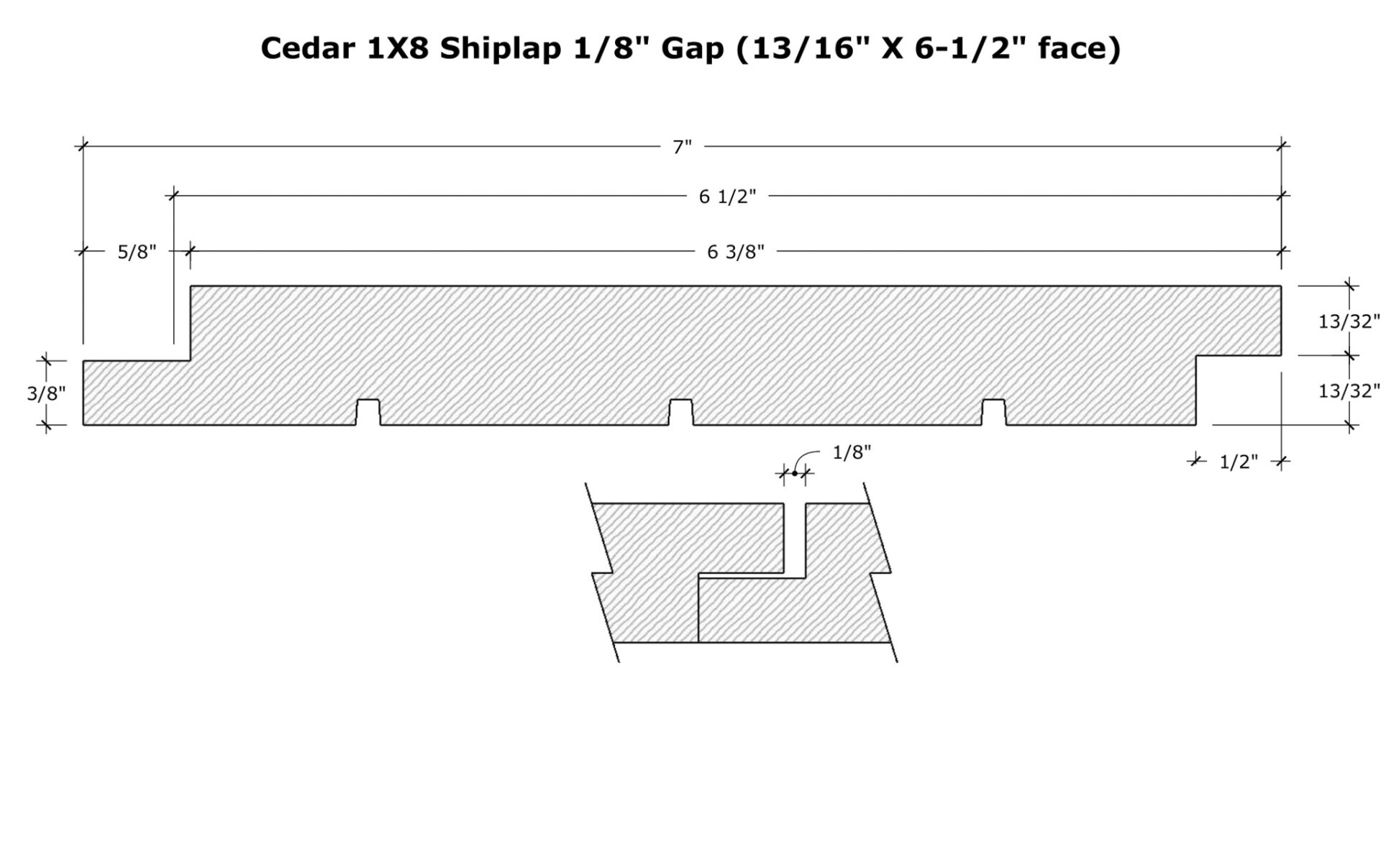

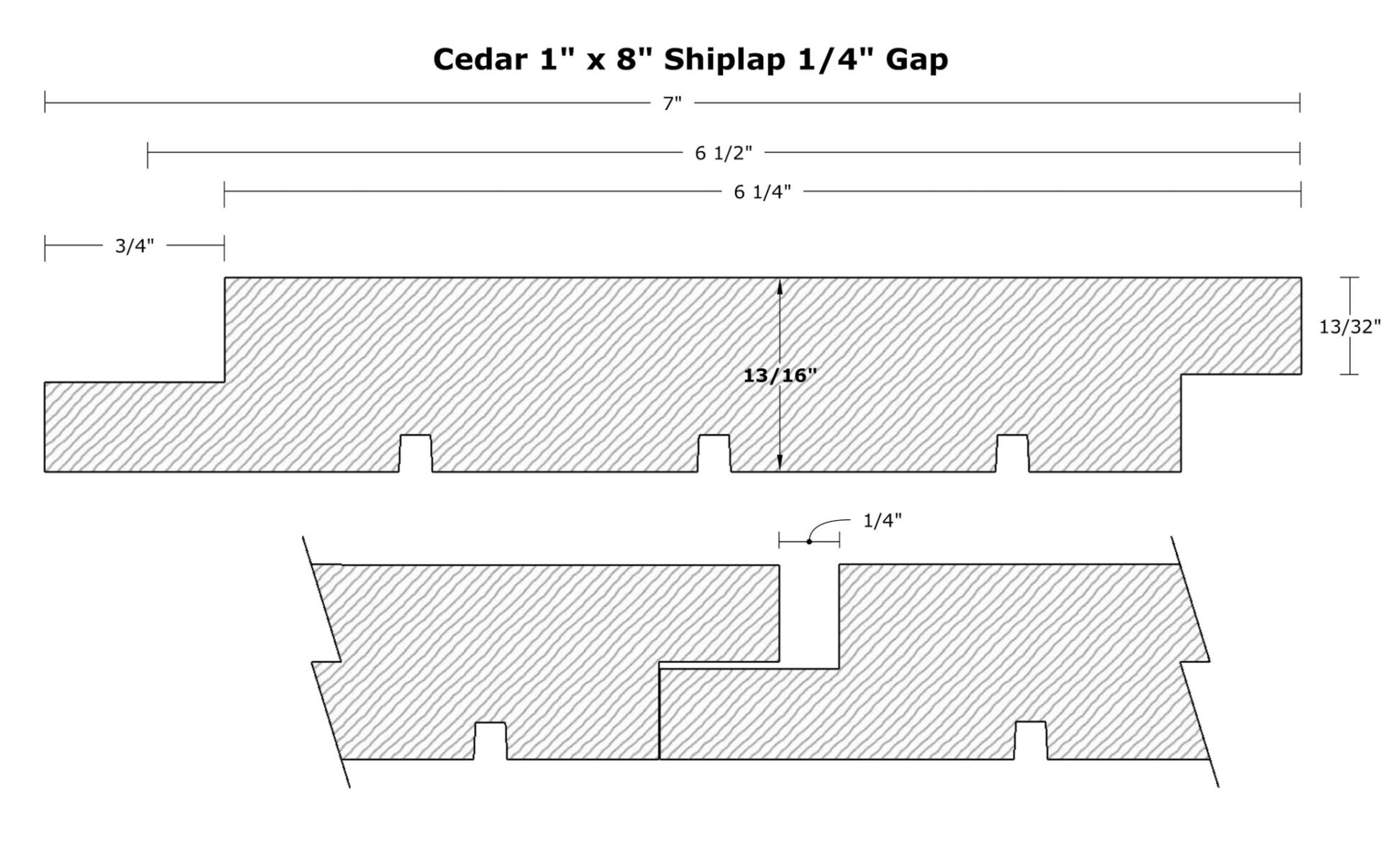

Standard Milling Profiles

Hewn’s Exterior Cedar Siding is available in a variety of milling profiles, designed to fit the individual needs of your project. Our most common milling profiles, listed on this page, assume our standard thickness of 13/16”.

Our Exterior Cedar Siding is milled to your requested specifications in-house, allowing for the highest level of oversight throughout the entire production process.

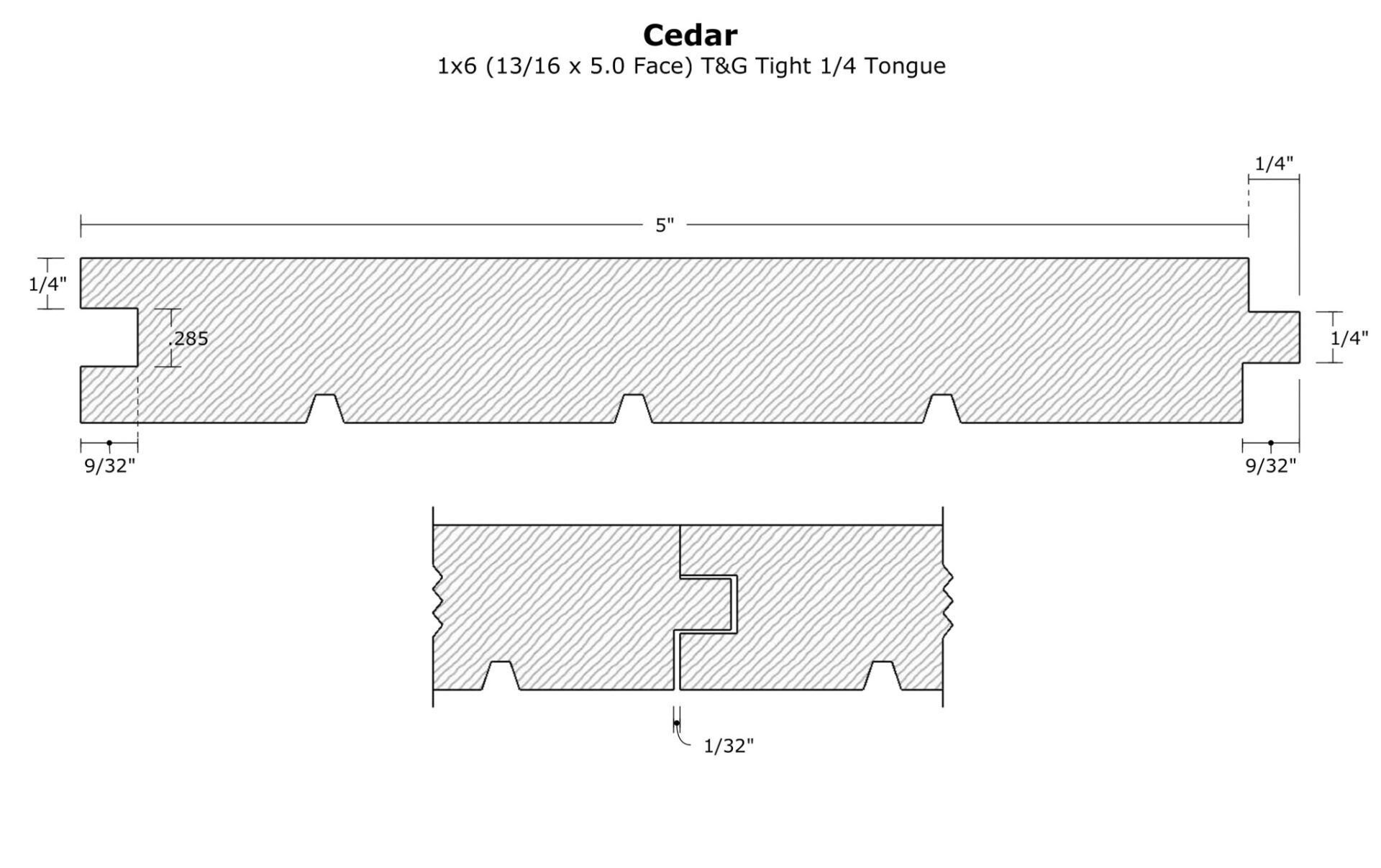

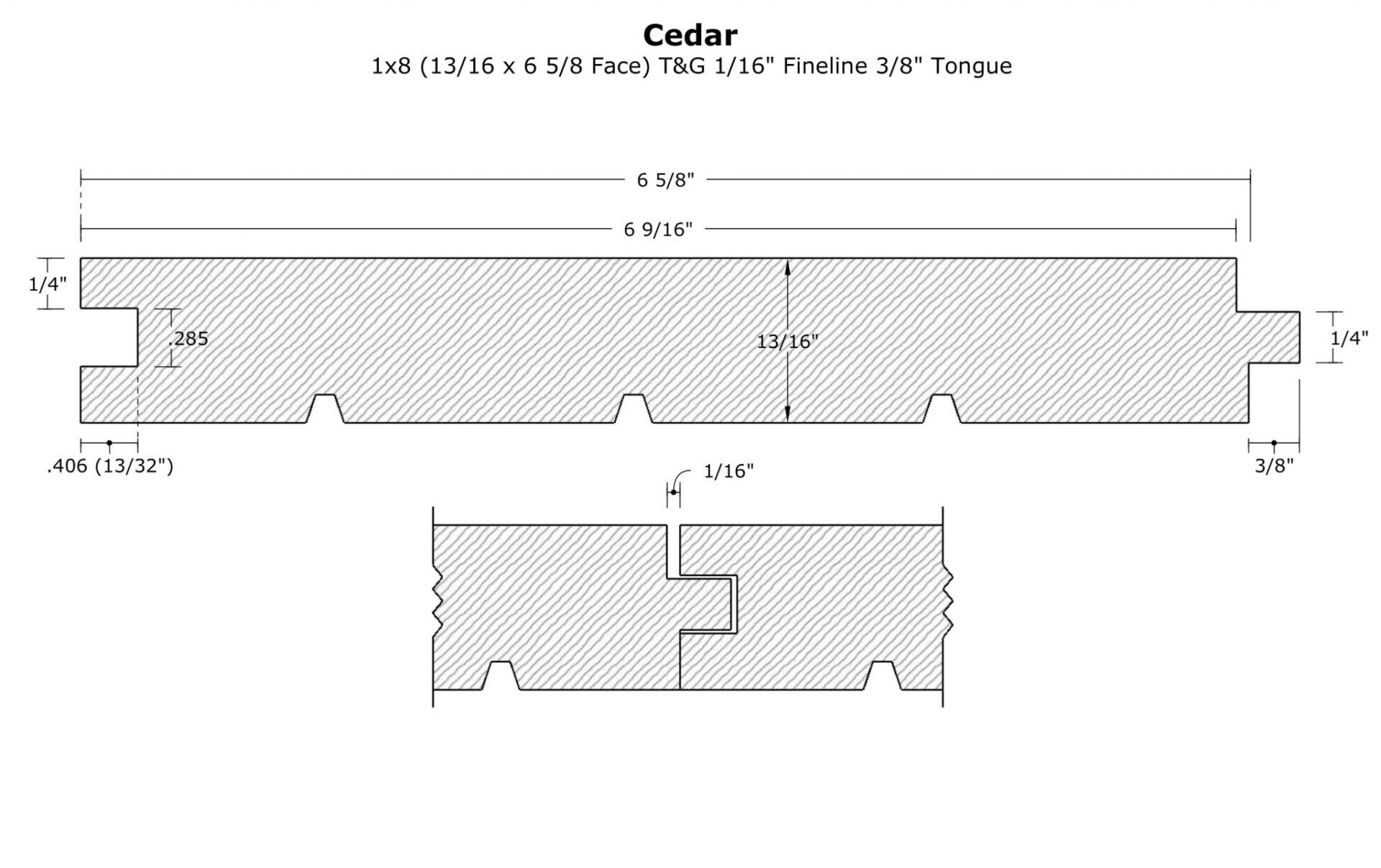

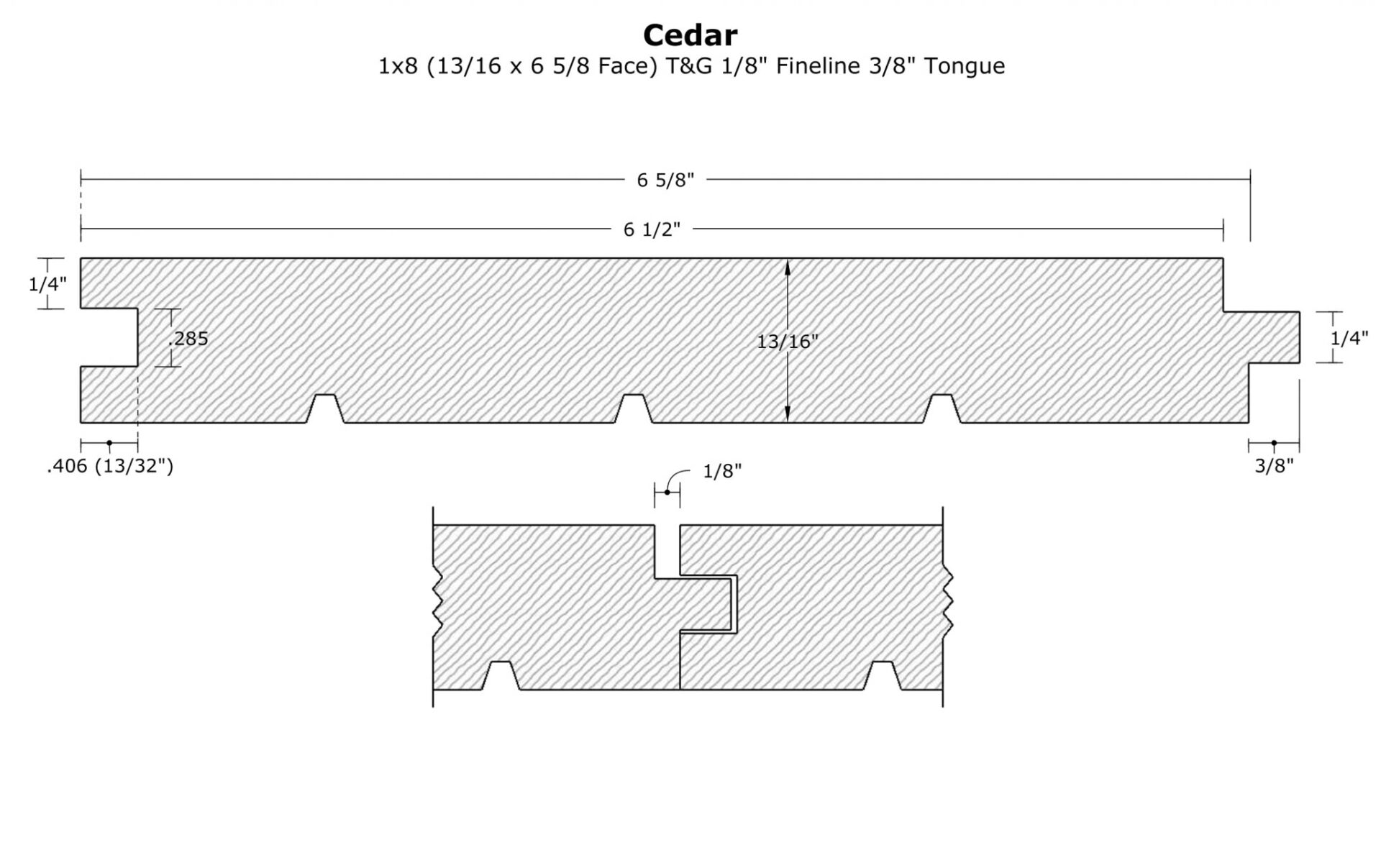

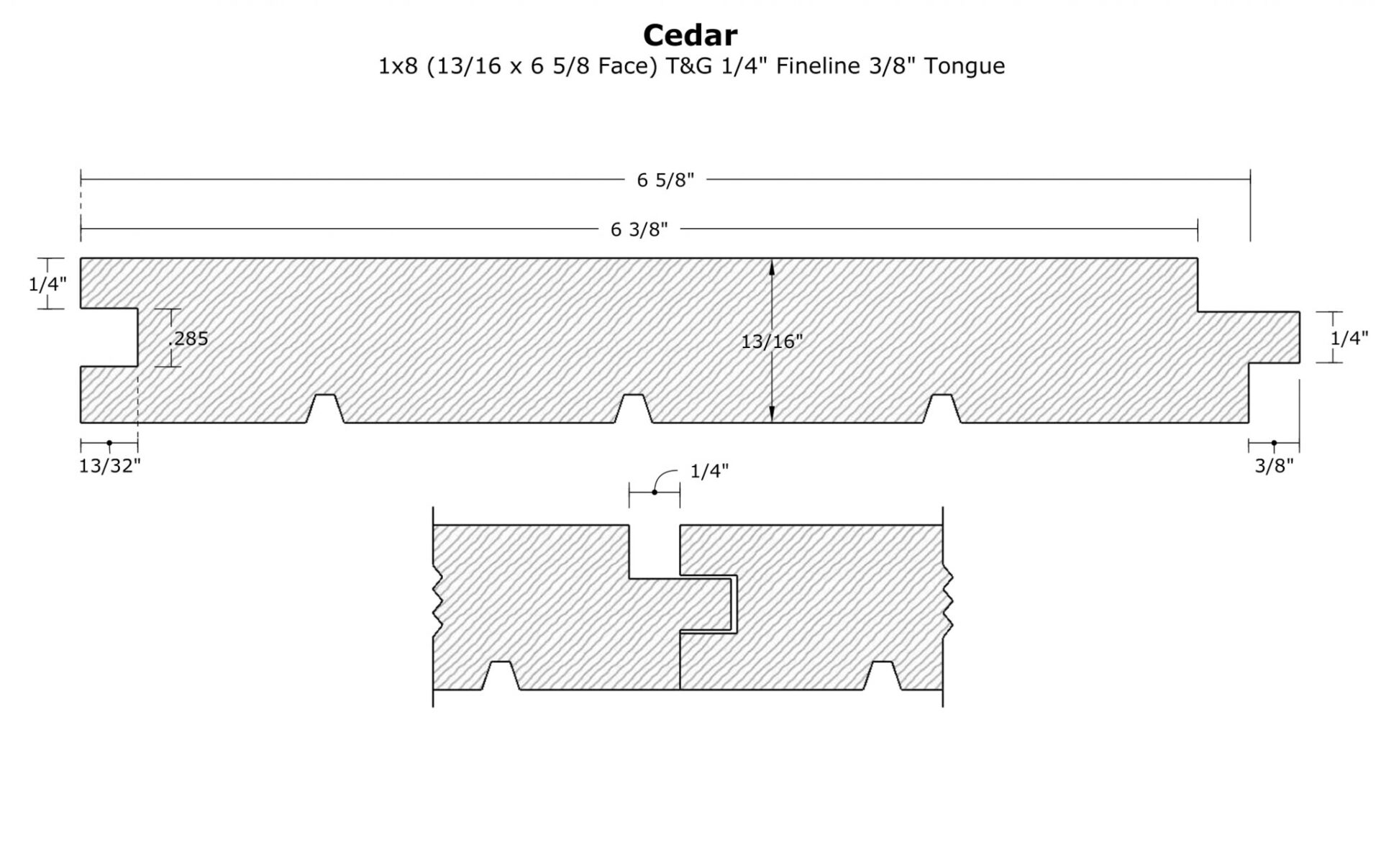

T&G Milling Profiles

Hewn’s Exterior Cedar Siding is sold in widths of 1×4, 1×6, 1×8, 1×10, and 1×12. T&G 1×4 and 1×6 profiles come standard with a ¼” tongue. T&G 1×8, 1×10, and 1×12 T&G profiles require a ⅜” tongue, instead of a ¼” tongue. Profiles for our most common widths (1×6 and 1×8) are shown below. For more profiles, please refer to our Specification Sheet.

Hewn has the capability to create custom milling knives in-house. For more information on custom milling options, please contact one of our sales representatives.

1x6 T&G Milling Profiles

1x8 T&G Milling Profiles*

* 1×8, 1×10, and 1×12 T&G profiles require a ⅜” tongue, instead of a ¼” tongue.

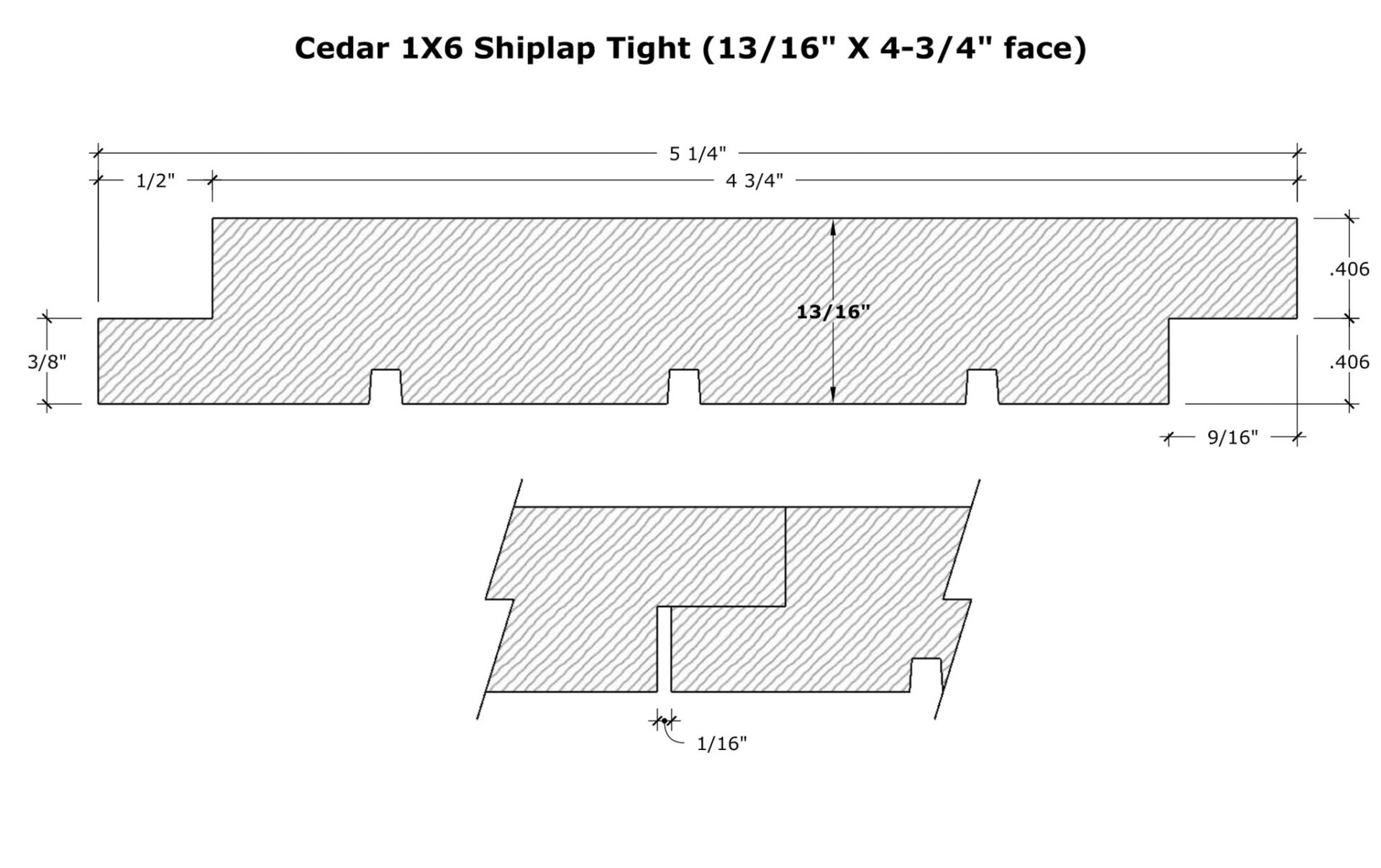

Shiplap Profiles

Hewn’s Exterior Cedar Siding is sold in widths of 1×4, 1×6, 1×8, 1×10, and 1×12. Profiles for our most common widths (1×6 and 1×8) are shown below. For more profiles, please refer to our Specification Sheet.

Hewn has the capability to create custom milling knives in-house. For more information on custom milling options, please contact one of our sales representatives.

1x6 Shiplap Milling Profiles

1x8 Shiplap Milling Profiles

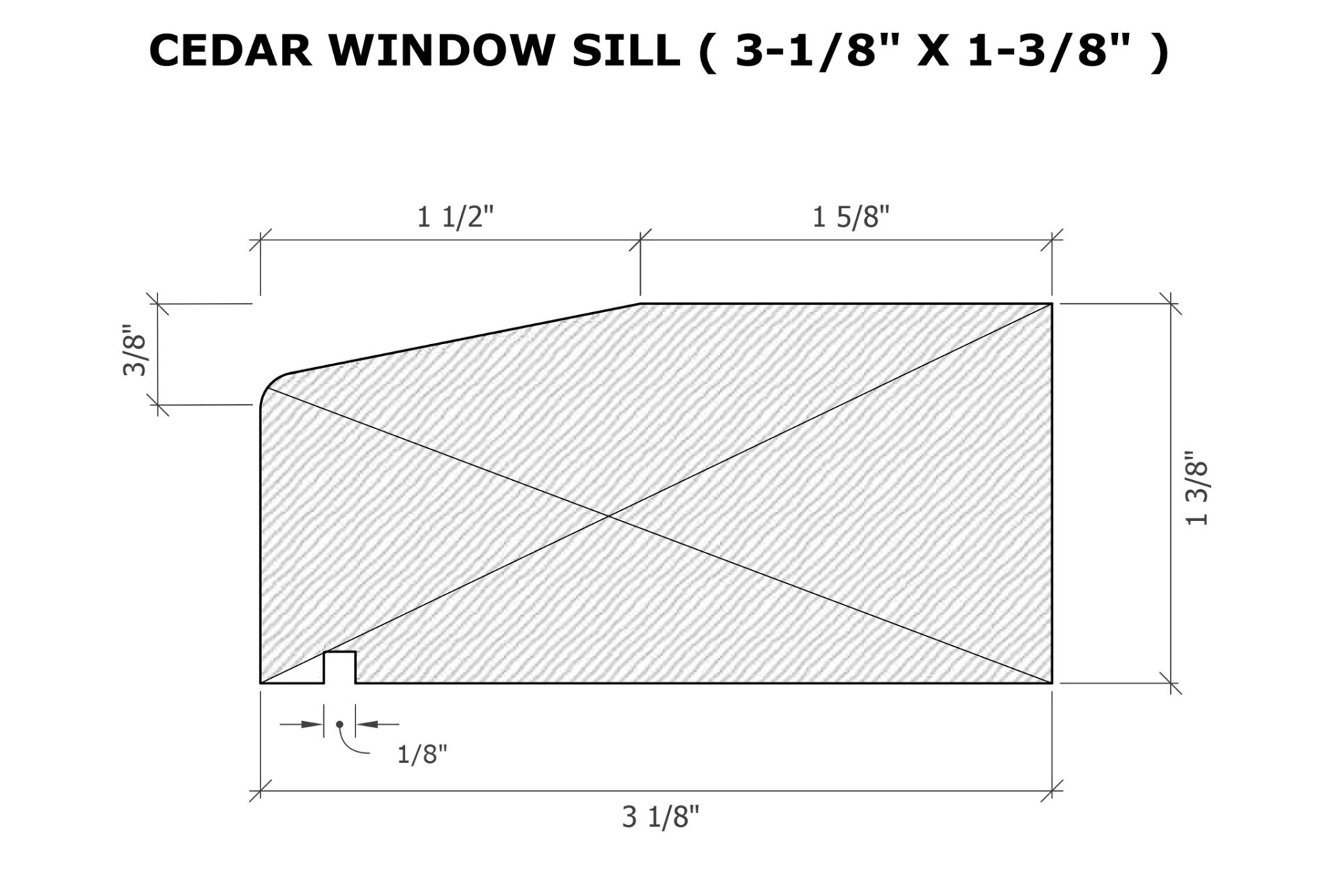

Exterior Siding Accessory Profiles

Standard Milling Profile Widths

Square Edge

1×4 (3½” face)

1×6 (5½” face)

1×8 (7¼” face)

1×10 (9¼” face)

1×12 (11¼” face)

Tongue & Groove

1×4 (3⅛” face)

1×6 (5″ face)

1×8 (6 ⅝” face)

1×10 (8 ⅝” face)

1×12 (10 ⅝” face)

Shiplap

1×4 (2¾” face)

1×6 (4¾” face)

1×8 (6½” face)

1×10 (8½” face)

1×12 (10½” face)