Class A Exterior Pressure Treated Fire Resistant Siding

Hewn believes that the quest for safer, fire-resistant siding should not result in sub-par products that mimic the look of wood siding. Wood siding has a long history of use in North America, and we aim to continue these generations-old traditions by developing real-wood exterior siding that is designed to meet the ever-increasing need for fire safety in our changing natural landscape.

Our Class A Exterior Pressure Treated Fire Retardant Lumber maintains the visual look and feel of our traditional exterior cedar siding, while implementing an industry-leading fire treatment process that modifies the wood to its core. These products resist the spread of fire, helping your project meet any major fire codes present in your area, and protecting your property in ways that were previously out of reach on a commercial scale.

In addition to their fire resistant properties, our treatment process has the added benefit of slowing the aging process of the wood itself, protecting against ultraviolet degradation and extending the lifetime of the material.

Our fire resistant products are subjected to industry-standard accelerated weathering tests (ASTM D-2898), Flame Spread (ASTM D-84), and are verified by International Code Counsel ESR-1159 and ESL-1021.

Colors

Samples of our Class A Fire Resistant Exterior Cedar Siding are available for online purchase. Please allow up to ten business days for production.

Specifications

Wood Species

Western Red Cedar

Grade

Select Tight Knot

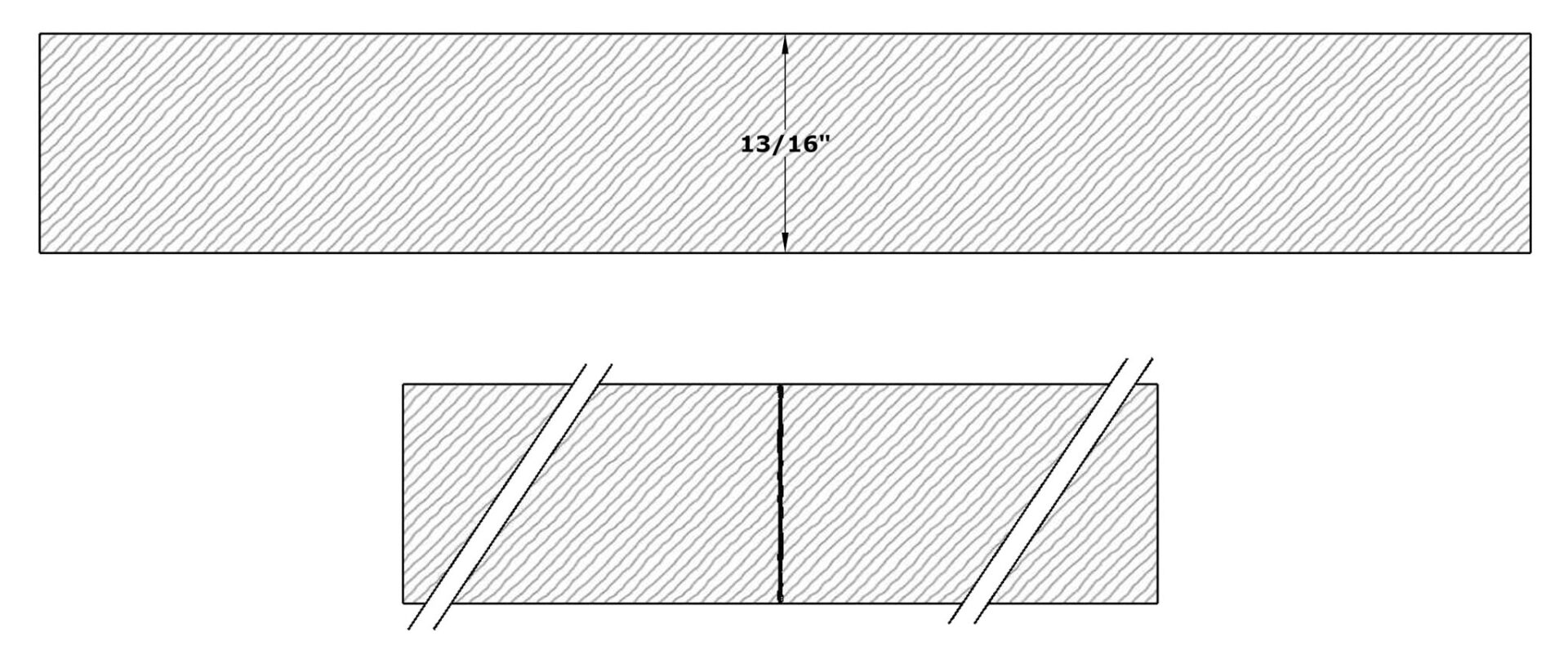

Standard Thickness

13/16″

Standard Widths (Nominal)

1×4, 1×6, 1×8, 1×10, 1×12

Milling Profile

Tongue & Groove or Shiplap (Multiple Options)

Moisture Content

Kiln Dried – Average 10-14%

Fire Resistance

Hewn Thermex-FR®

Process Type

Vacuum-Impregnated Treatment

Class Rating

Class A (ASTM E84)

Possible LEED Credits

MR 5 – Regional Materials

Flame Spread Index

25 (or less)

V.O.C. Content

< 550 g/L

Smoke Developed Index

45 (or less)

Testing Lab

QAI Laboratories

Report Number

IAS Report No. AA-635

Treatment Notes

ICC ES Report ESR-1159 ESL 1021. Tested per ASTM E84 / UL 723. Extended for 30 min, no increase in listed classification subjected to standard rain test (ASTM D2898). KDAT.

Visible & Decorative Metals with Class A Siding

Class A Exterior Cedar Siding contains elements that could react with metals on the building. It is recommended to use either a pre-painted baked enamel or stainless steel product for any metal on, or in contact with the building facade.

When using copper or any other non-coated metal, please coat the surface with a quality protective enamel finish. When possible, use 2 coats of quality protective enamel finish, which will help protect the metal from reacting to the Class A product.

Metals to Consider

- Windows

- Gutters

- Down Spouts

- Flashing

- Valleys

- Fixtures

* These metals will only be affected if they are sitting below your Class A Exterior Cedar Siding, as the elements would come into contact with the metal via rain and moisture running downward over the face of the building.

All Cedar Siding must be installed using only Stainless Steel fasteners.

Hewn advises against using anodized metals with our Class A Exterior Cedar Siding.

For any questions or concerns about using decorative metals with our Class A Siding, email us at info@hewn.com.

Standard Milling Profiles

Hewn’s Class A Fire Resistant Exterior Cedar Siding is available in a variety of milling profiles, designed to fit the individual needs of your project. Our most common milling profiles, listed on this page, assume our standard thickness of 13/16”.

Our Class A Fire Resistant Exterior Cedar Siding is milled to your requested specifications in-house, allowing for the highest level of oversight throughout the entire production process.

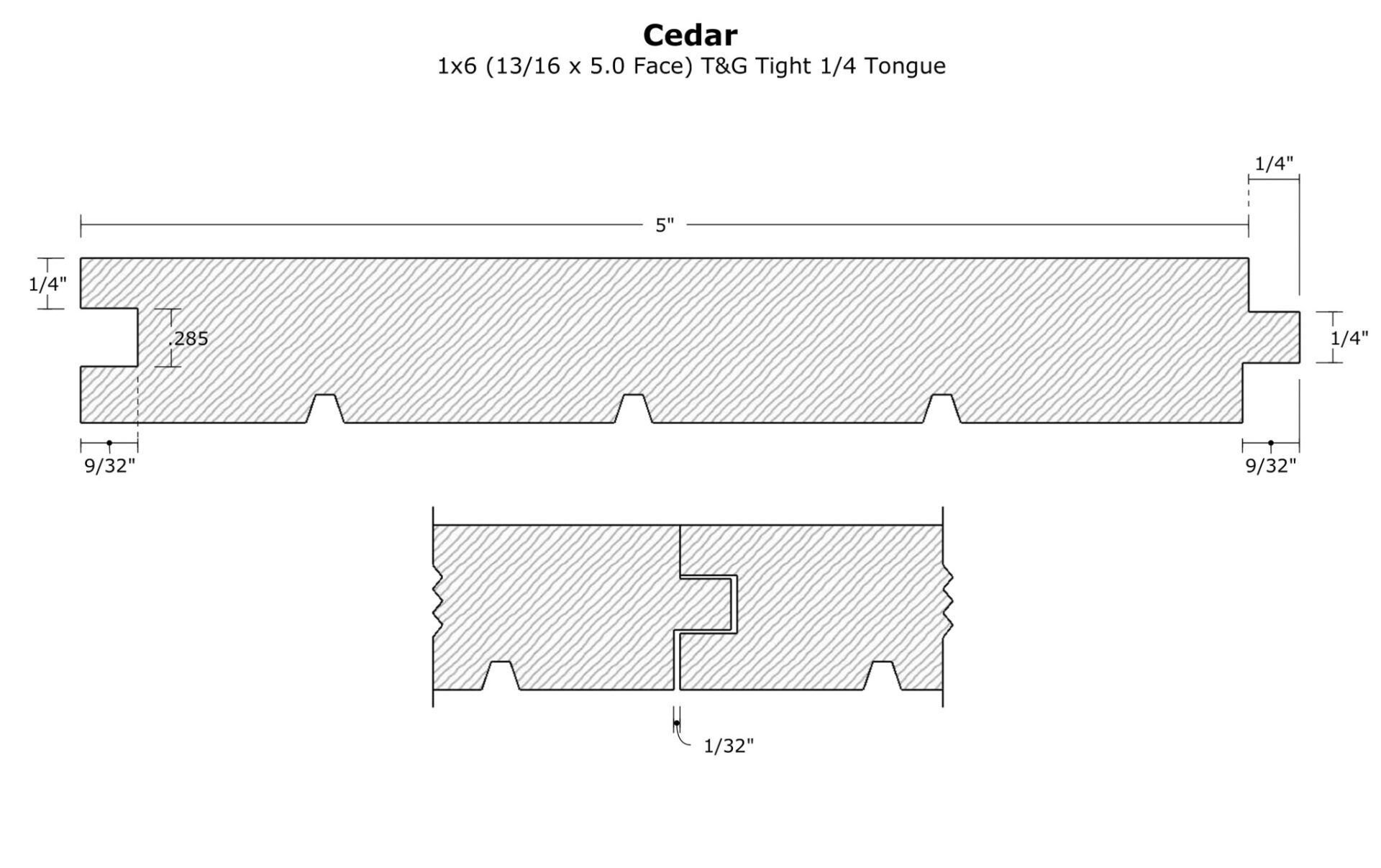

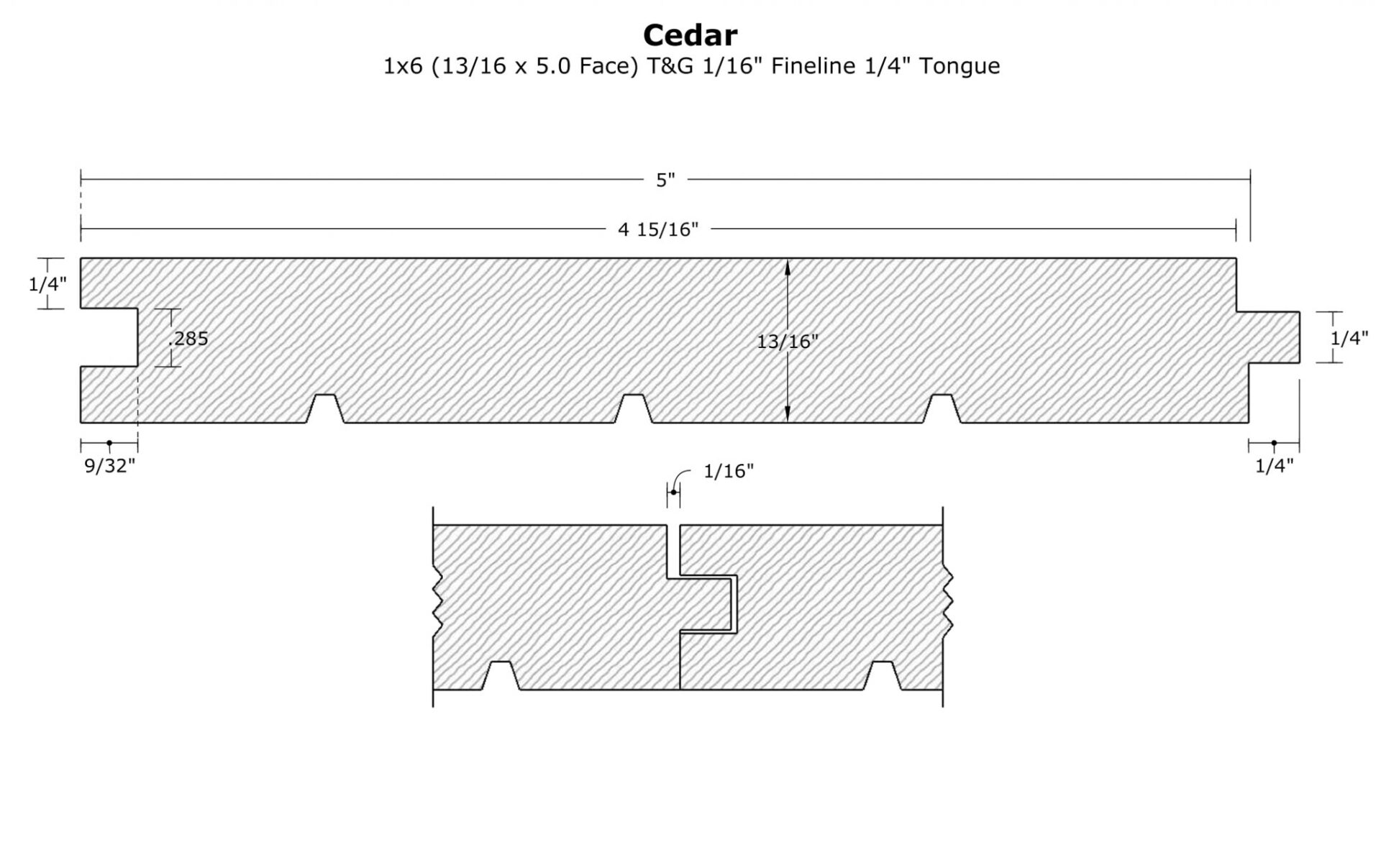

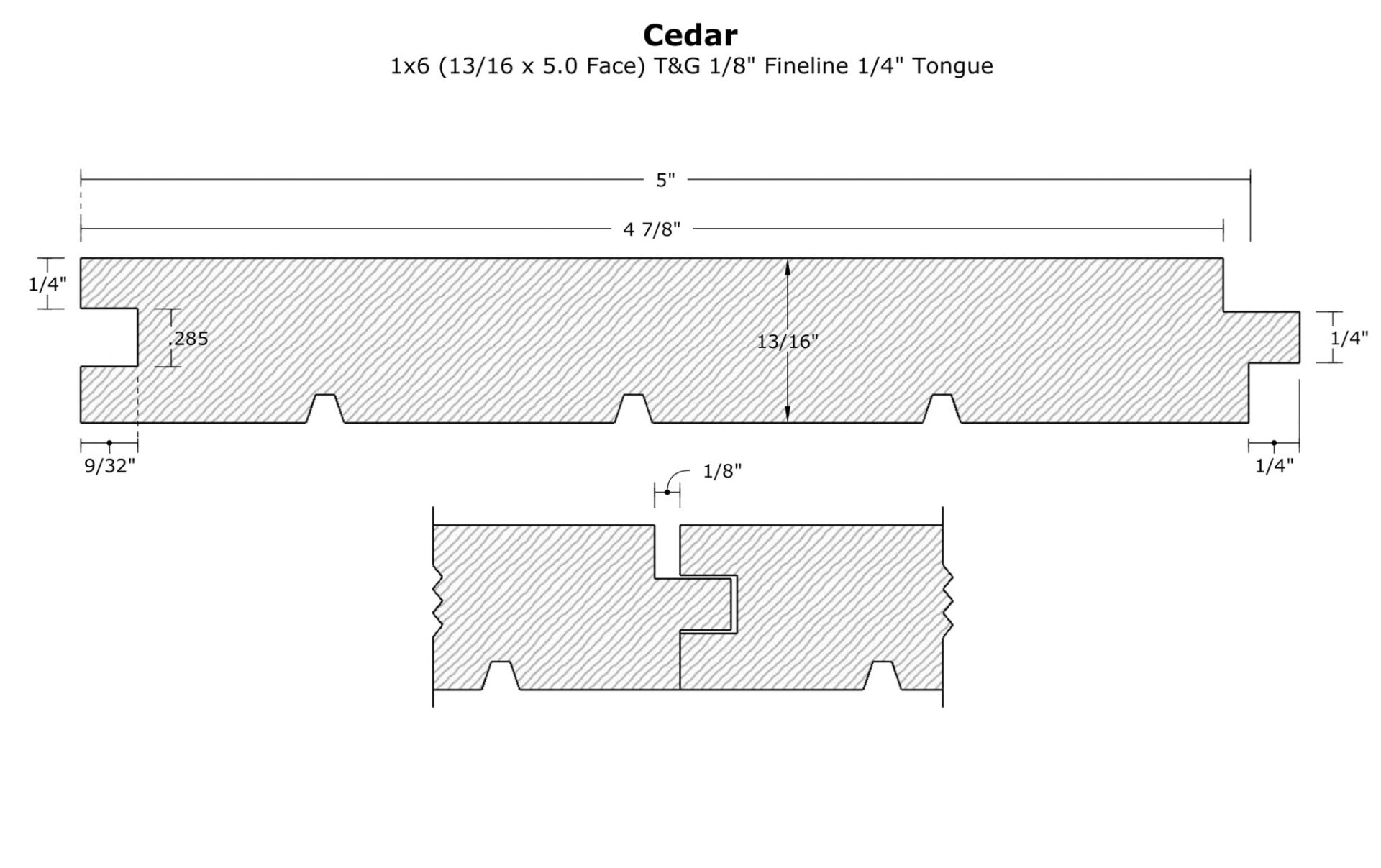

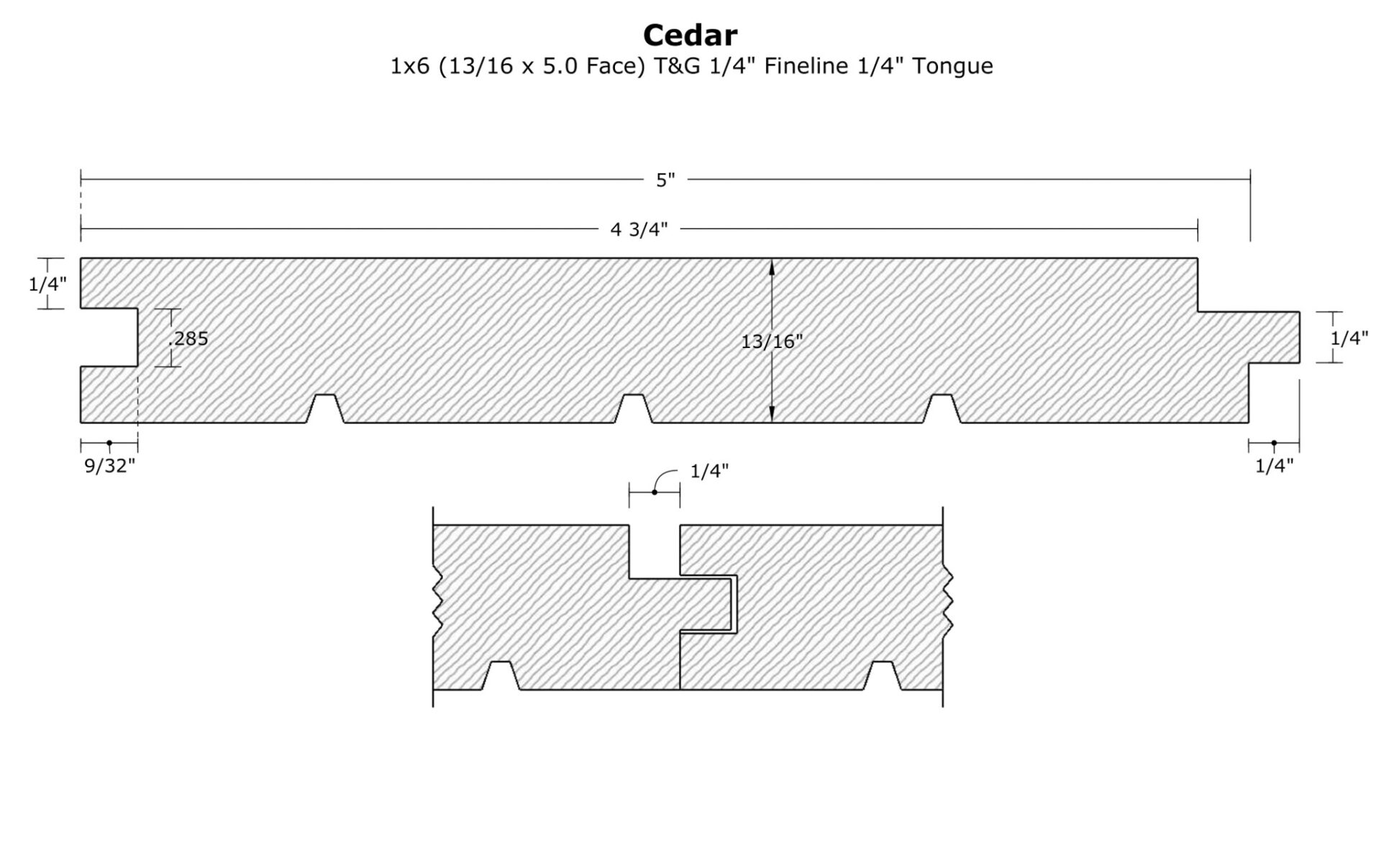

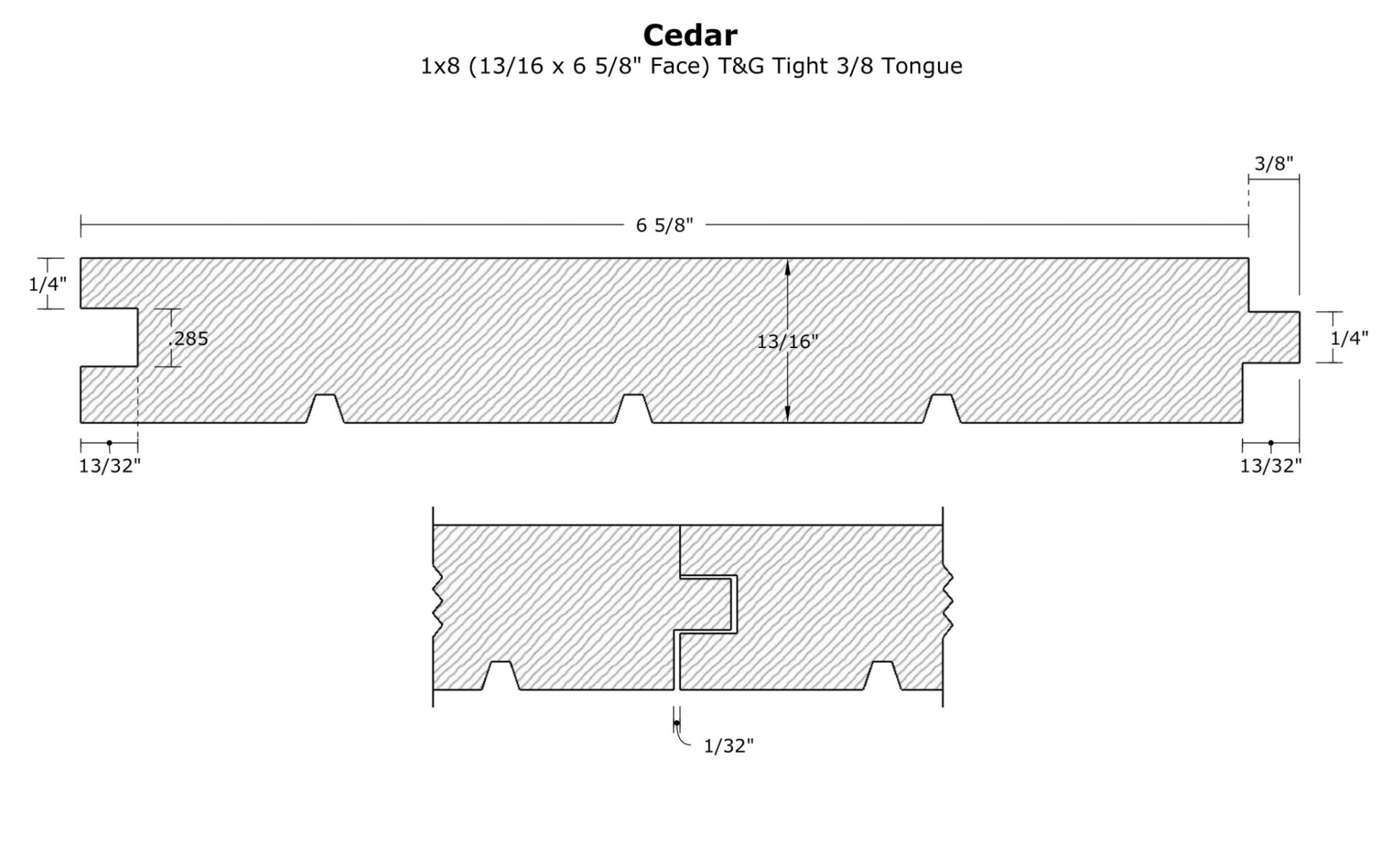

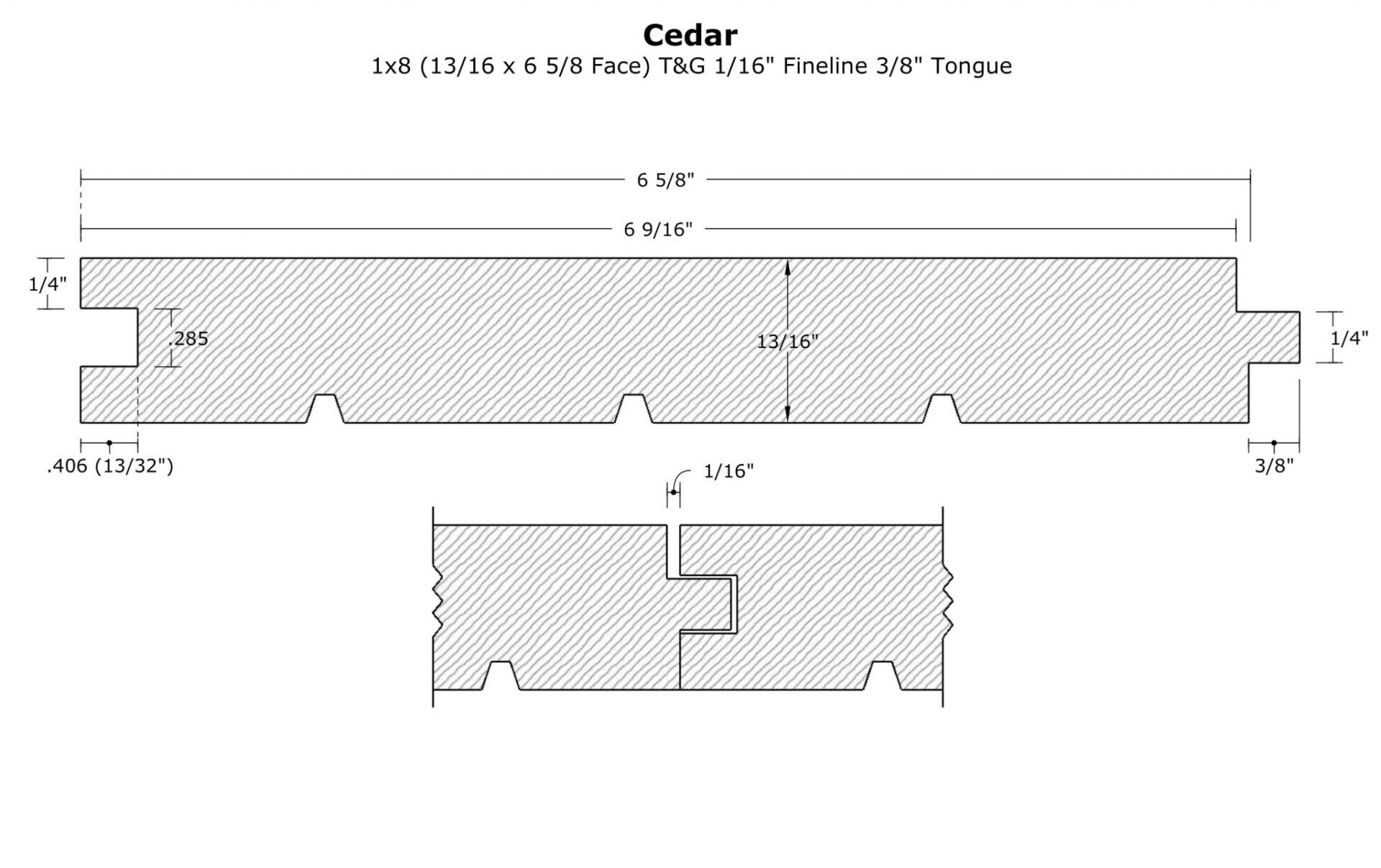

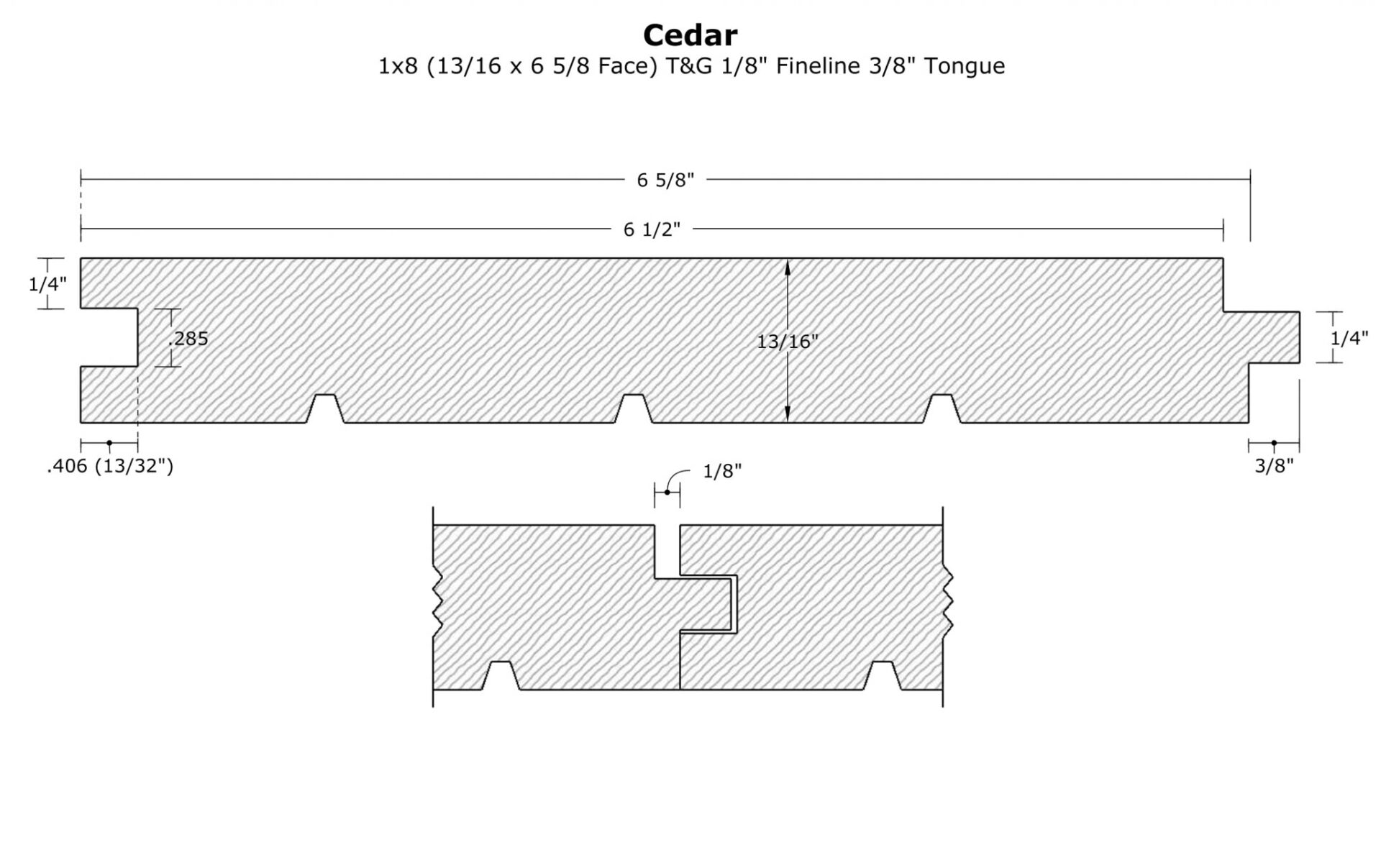

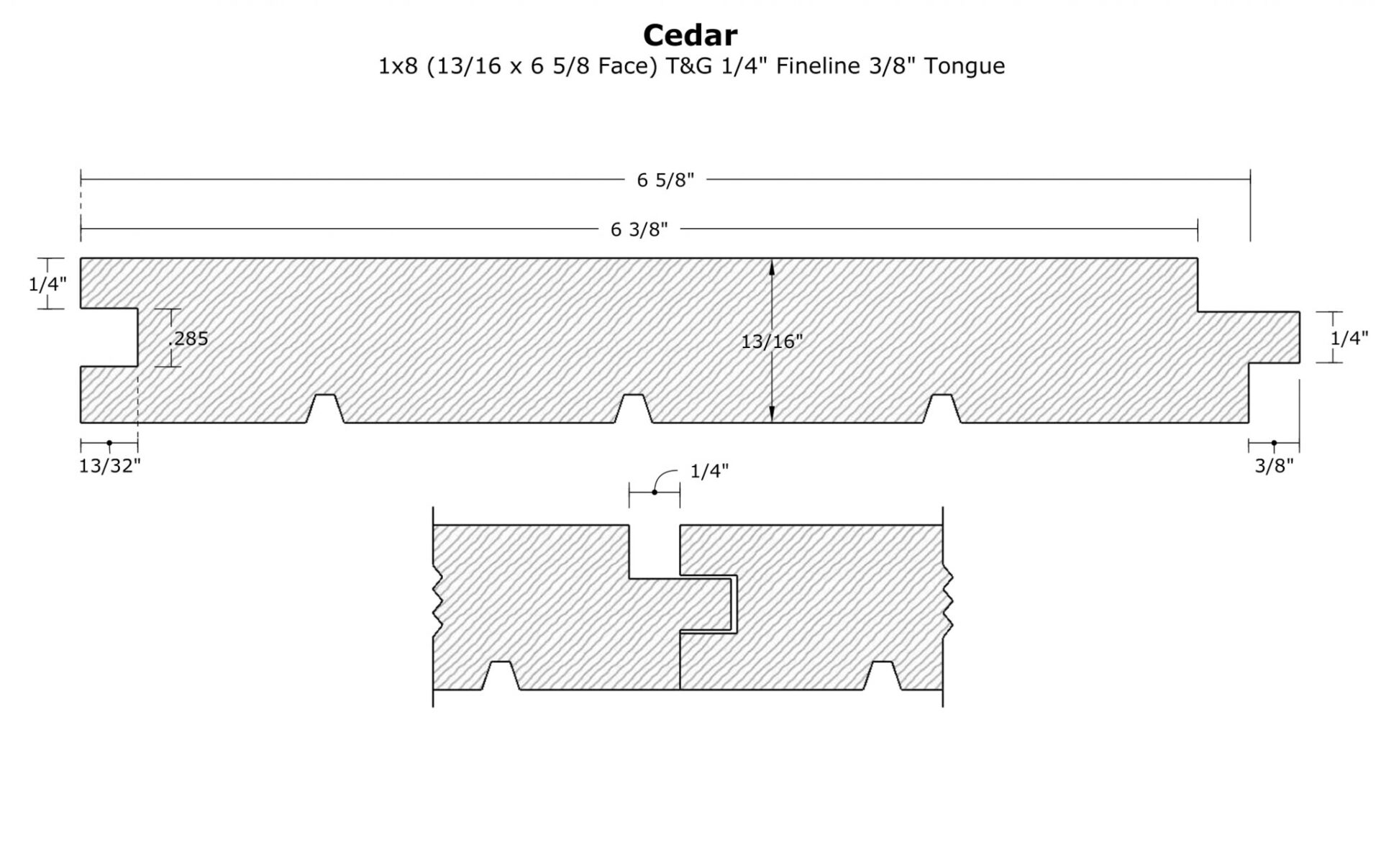

T&G Milling Profiles

Hewn’s Class A Fire Resistant Exterior Cedar Siding is sold in widths of 1×4, 1×6, 1×8, 1×10, and 1×12. T&G 1×4 and 1×6 profiles come standard with a ¼” tongue. T&G 1×8, 1×10, and 1×12 T&G profiles require a ⅜” tongue, instead of a ¼” tongue. Profiles for our most common widths (1×6 and 1×8) are shown below. For more profiles, please refer to our Specification Sheet.

Hewn has the capability to create custom milling knives in-house. For more information on custom milling options, please contact one of our sales representatives.

1x6 T&G Milling Profiles

1x8 T&G Milling Profiles*

* 1×8, 1×10, and 1×12 T&G profiles require a ⅜” tongue, instead of a ¼” tongue.

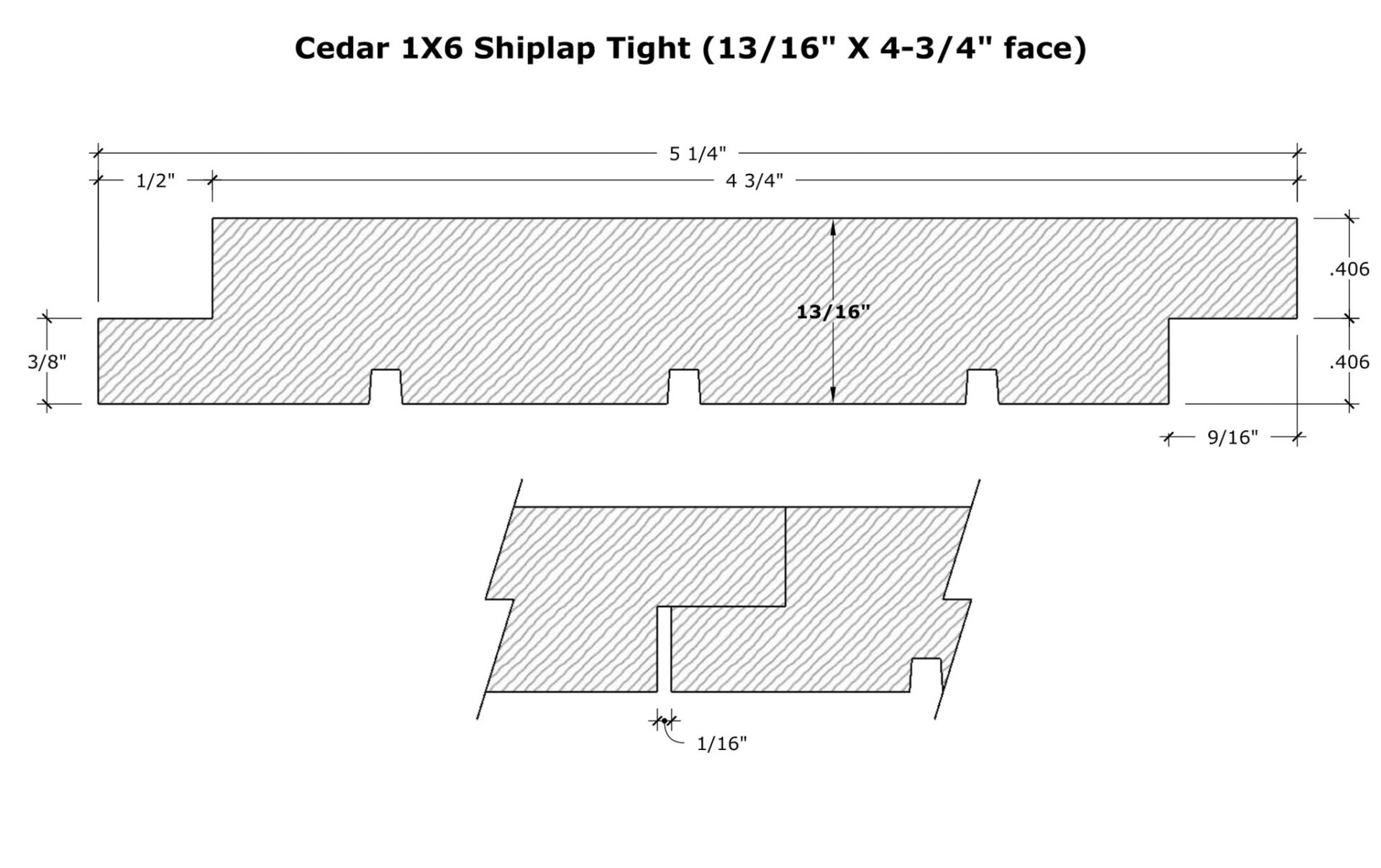

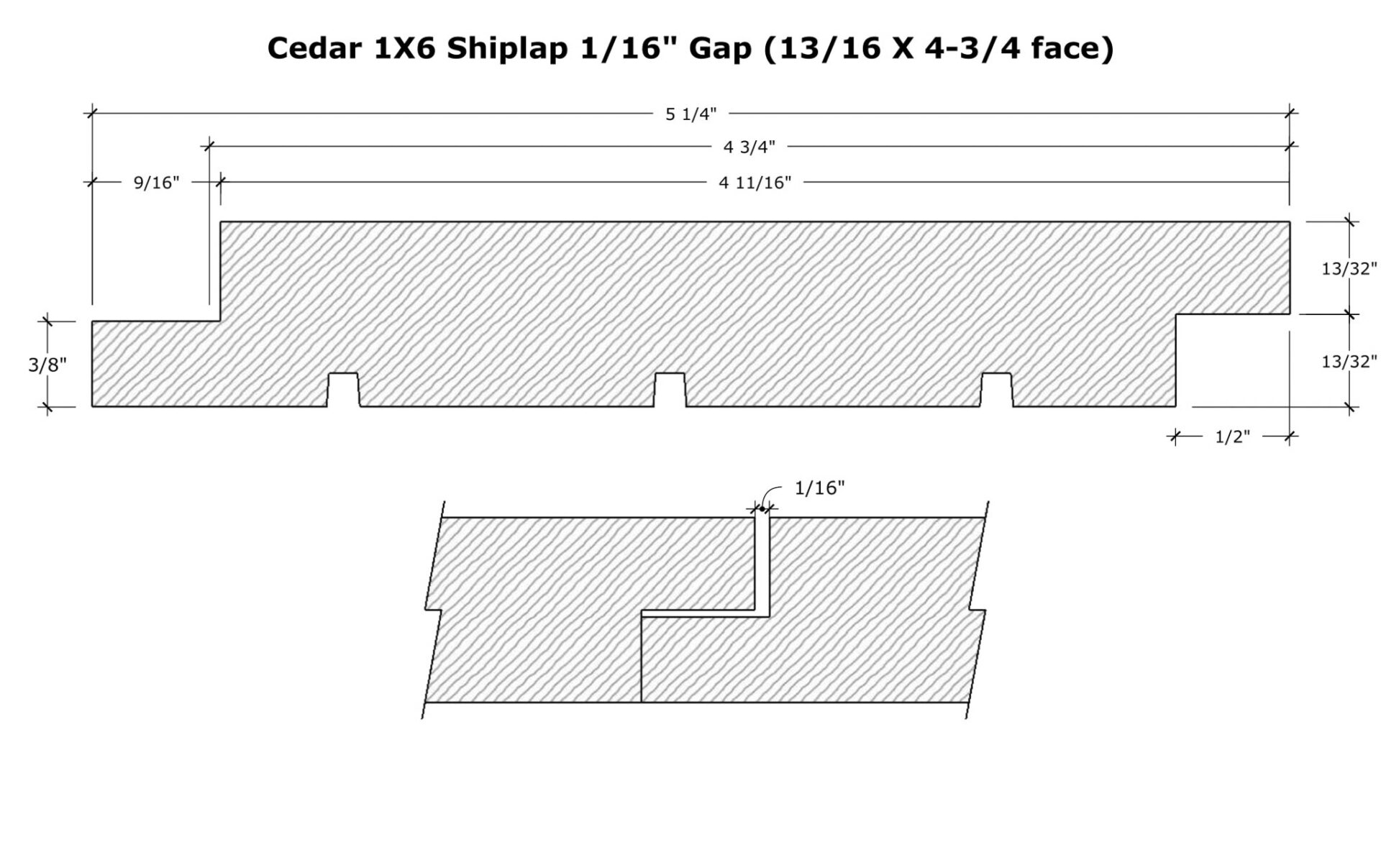

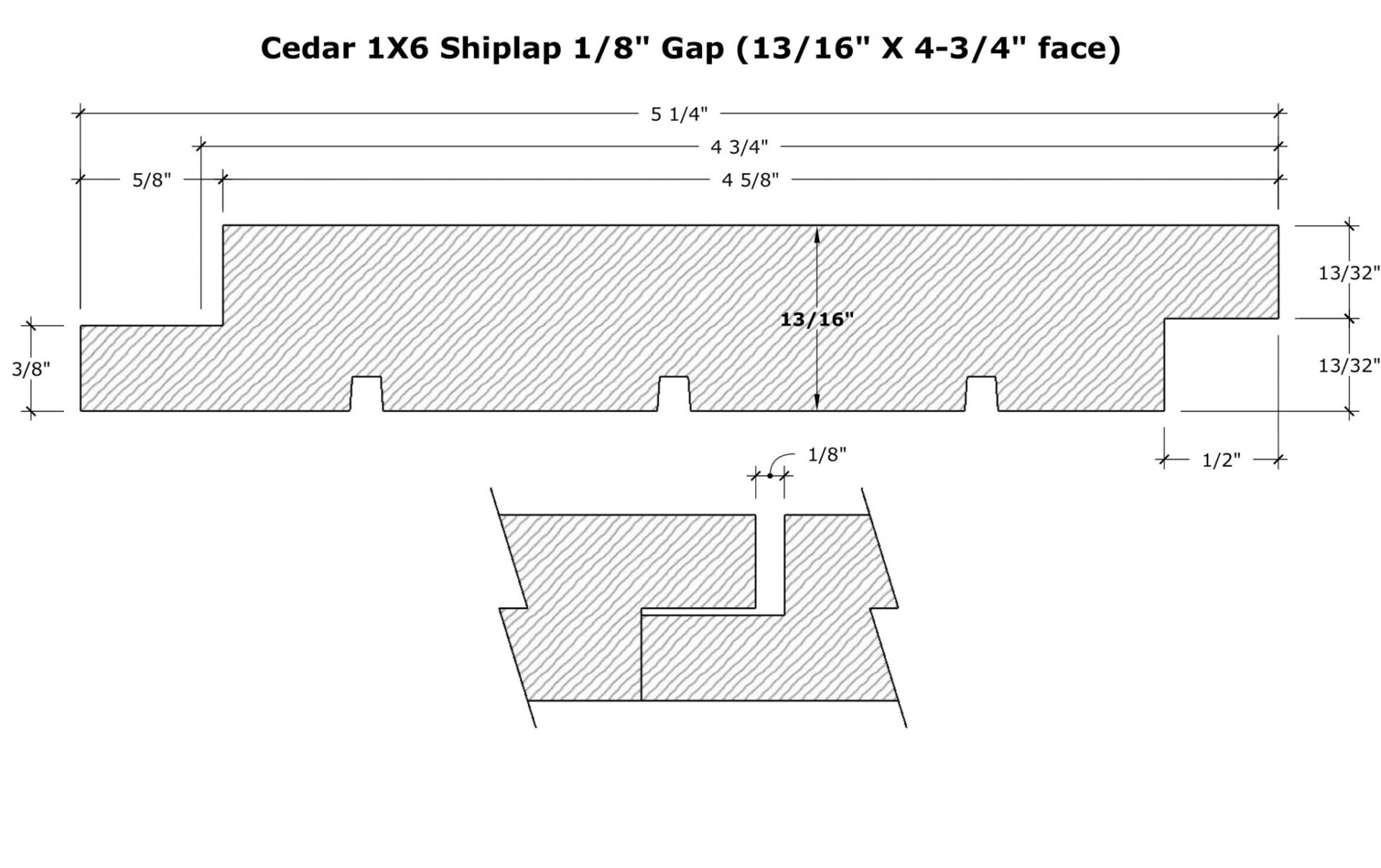

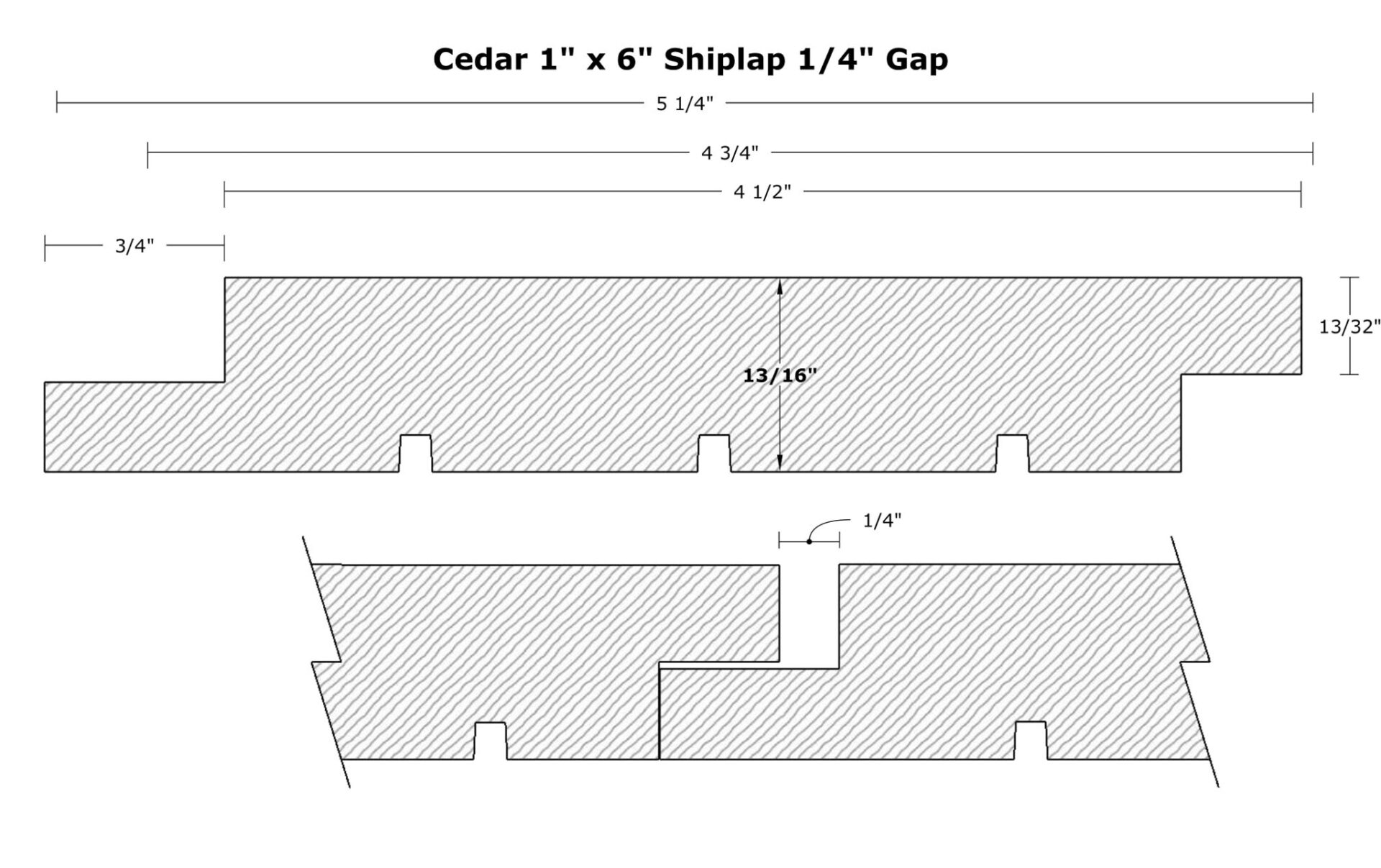

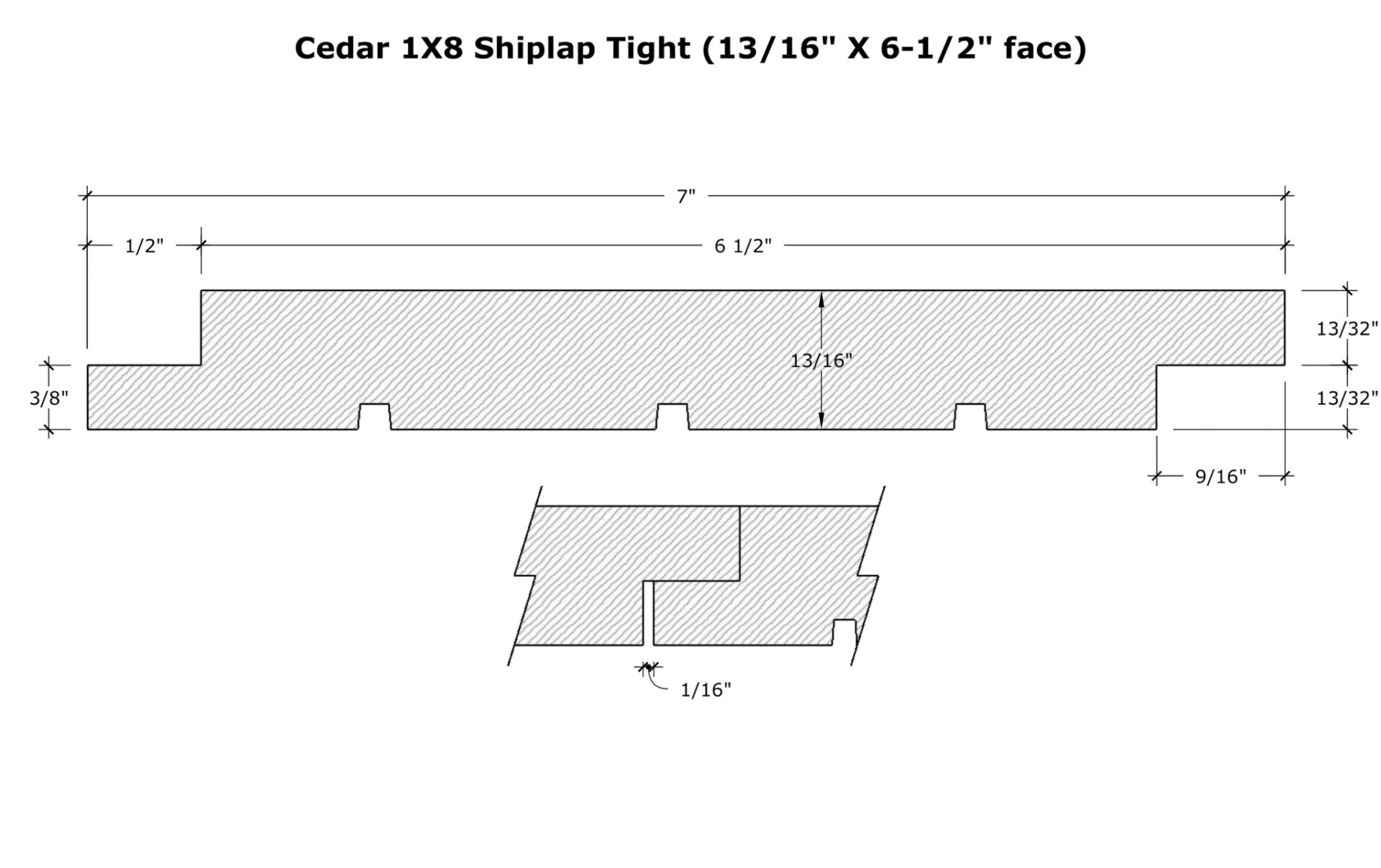

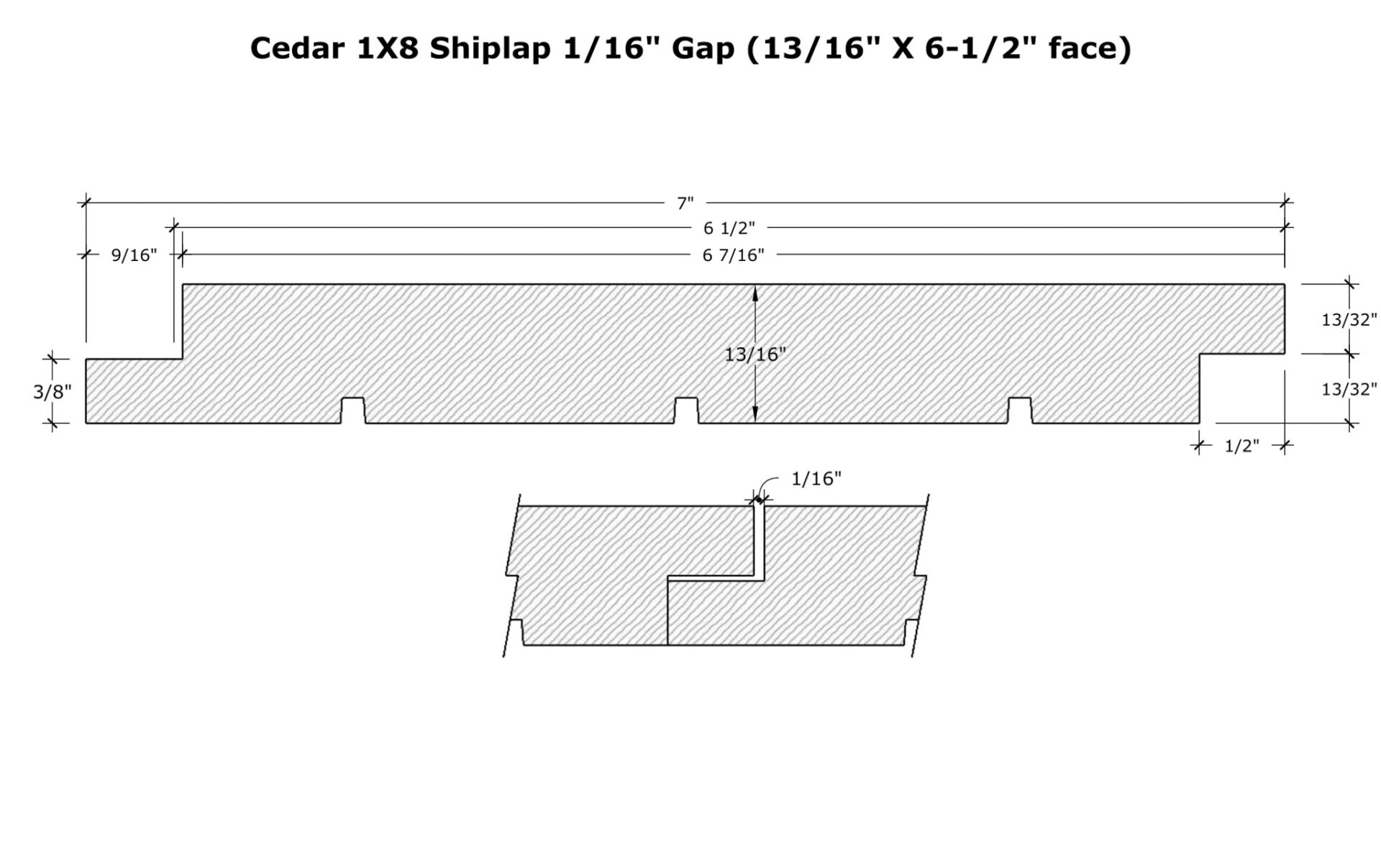

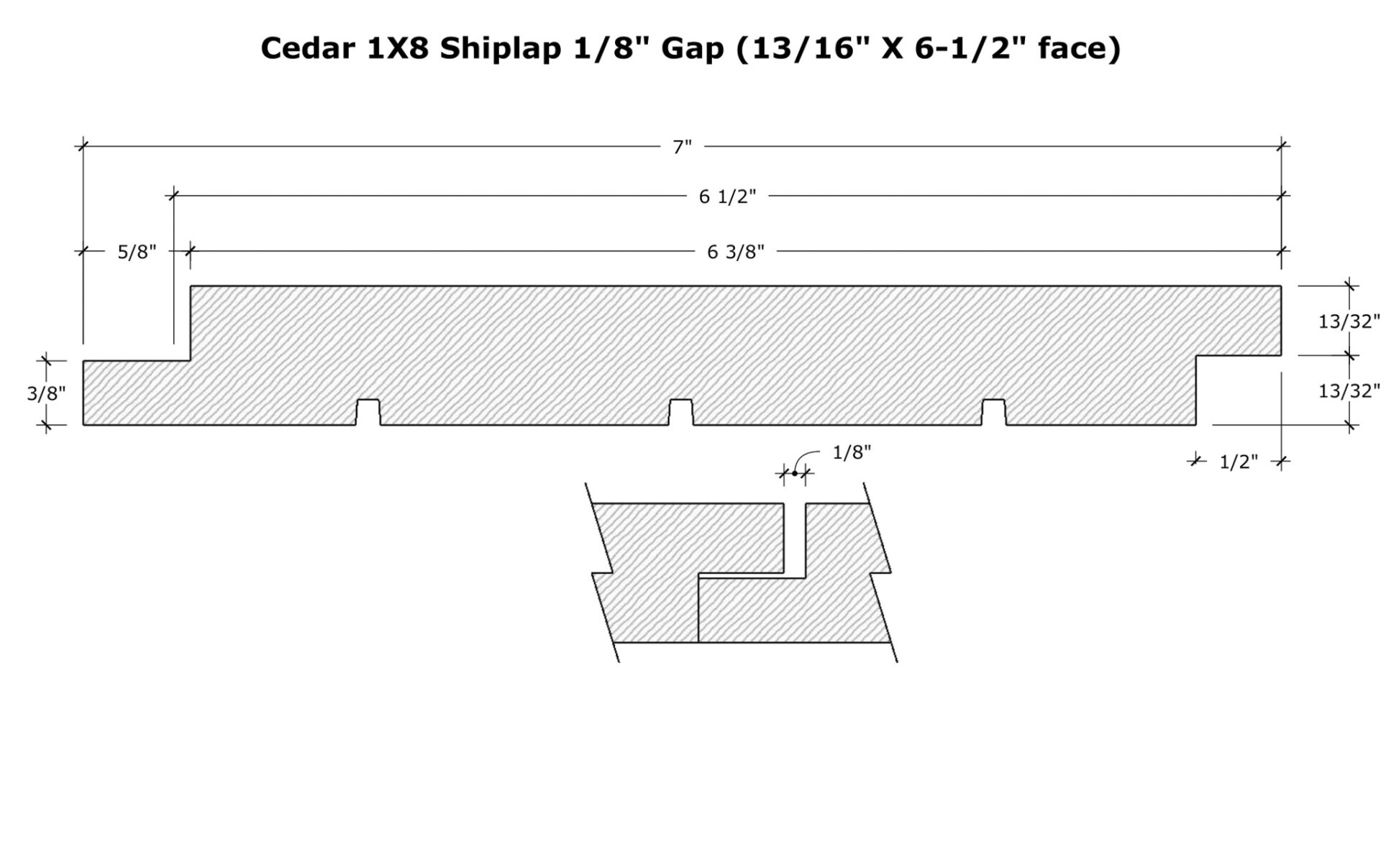

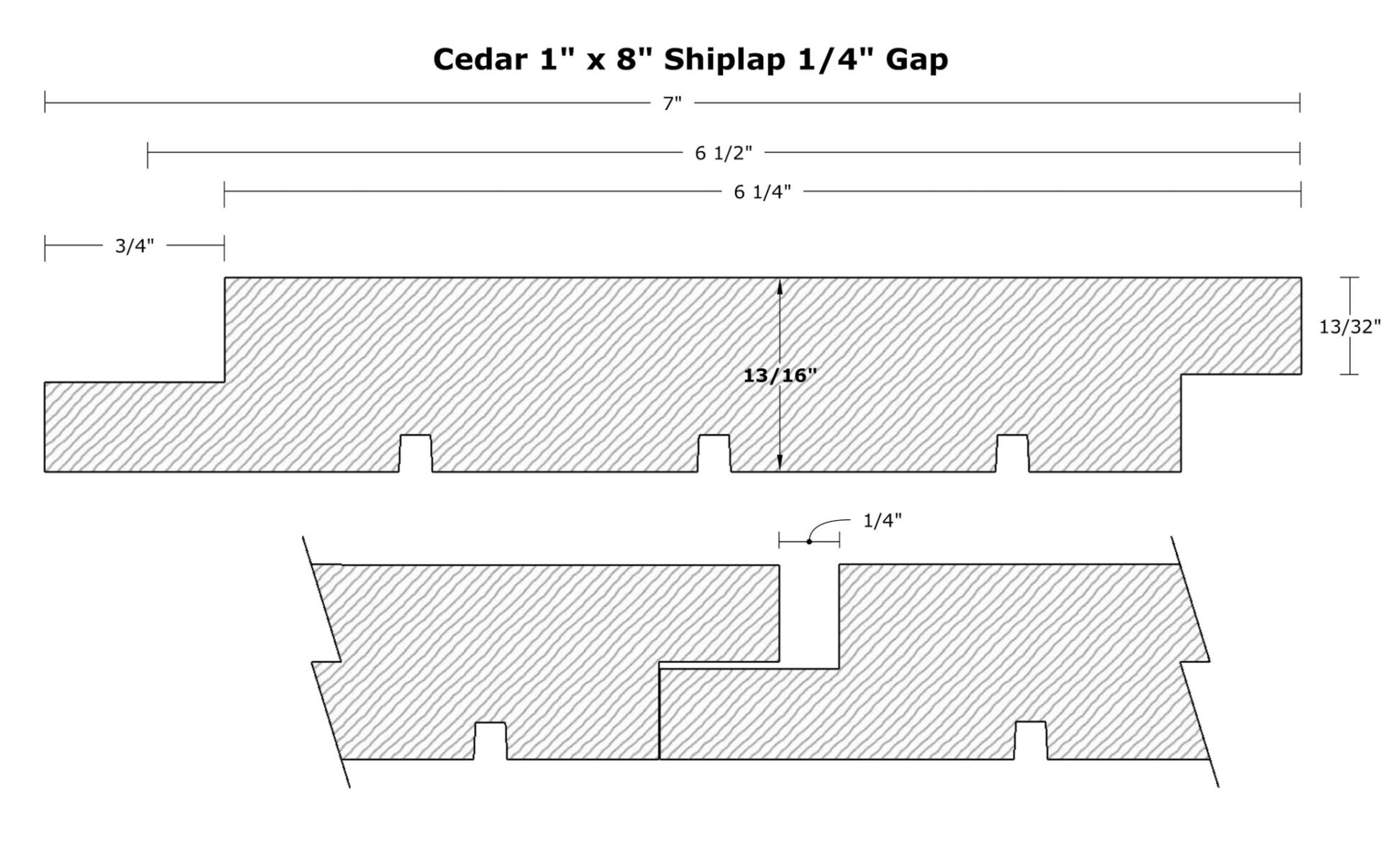

Shiplap Profiles

Hewn’s Class A Fire Resistant Exterior Cedar Siding is sold in widths of 1×4, 1×6, 1×8, 1×10, and 1×12. Profiles for our most common widths (1×6 and 1×8) are shown below. For more profiles, please refer to our Specification Sheet.

Hewn has the capability to create custom milling knives in-house. For more information on custom milling options, please contact one of our sales representatives.

1x6 Shiplap Milling Profiles

1x8 Shiplap Milling Profiles

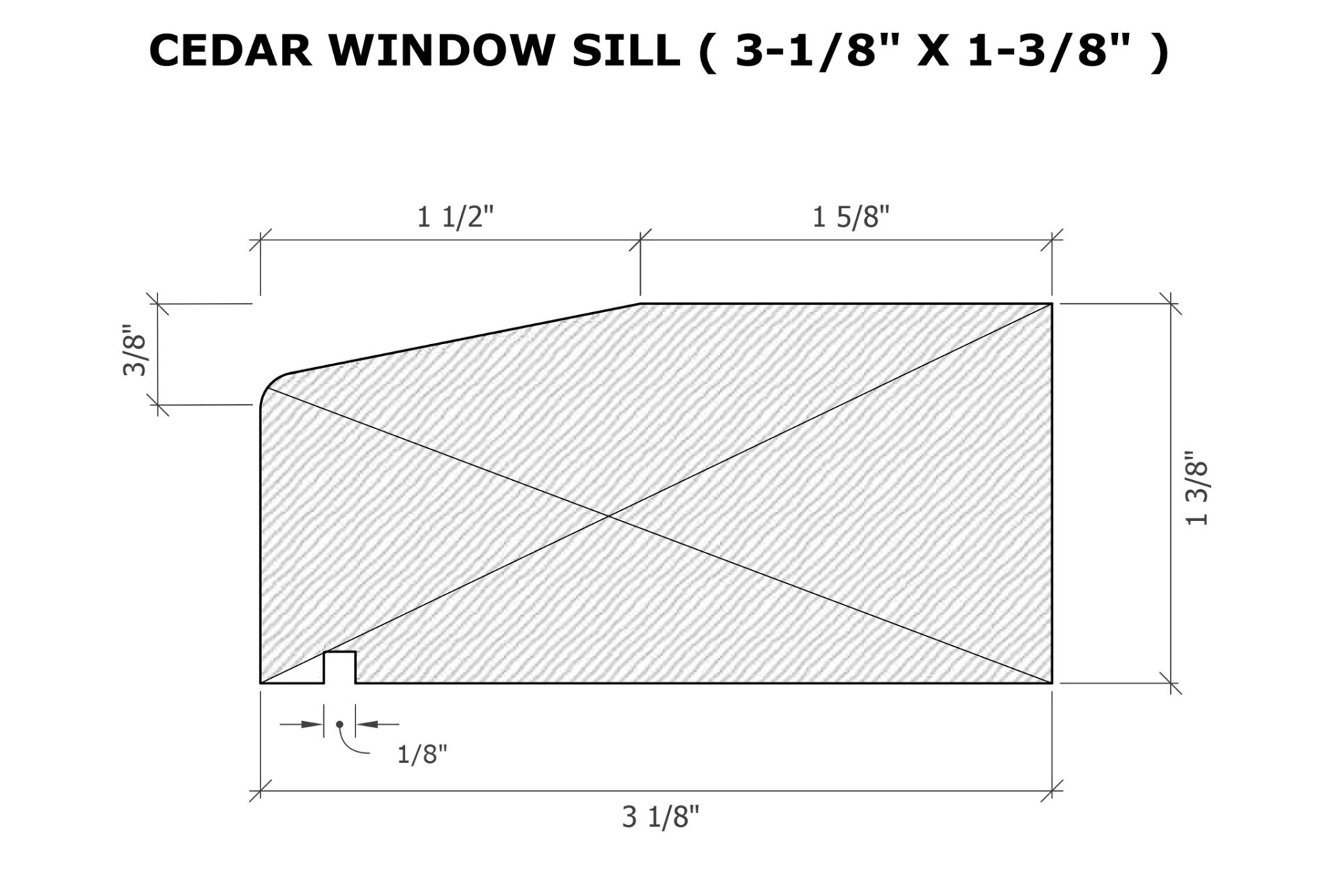

Exterior Siding Accessory Profiles

Standard Milling Profile Widths

Square Edge

1×4 (3½” face)

1×6 (5½” face)

1×8 (7¼” face)

1×10 (9¼” face)

1×12 (11¼” face)

Tongue & Groove

1×4 (3⅛” face)

1×6 (5″ face)

1×8 (6 ⅝” face)

1×10 (8 ⅝” face)

1×12 (10 ⅝” face)

Shiplap

1×4 (2¾” face)

1×6 (4¾” face)

1×8 (6½” face)

1×10 (8½” face)

1×12 (10½” face)

Fostering Local Partnerships

Hewn believes in the power of strong local economies. Our Class A Exterior Pressure Treated Fire Retardant Lumber is made in partnership with Chemco Inc, a local company here in the Pacific Northwest with forty years of experience in research and development of wood enhancement technology for fire-resistant products. We combine Chemco’s unmatched fire treatment processes with Hewn’s proprietary color and finishing techniques to create unique wood siding products designed for installation in the toughest of fire-code regions and environments, ensuring our customers a safe and beautiful product without compromise.